| 11

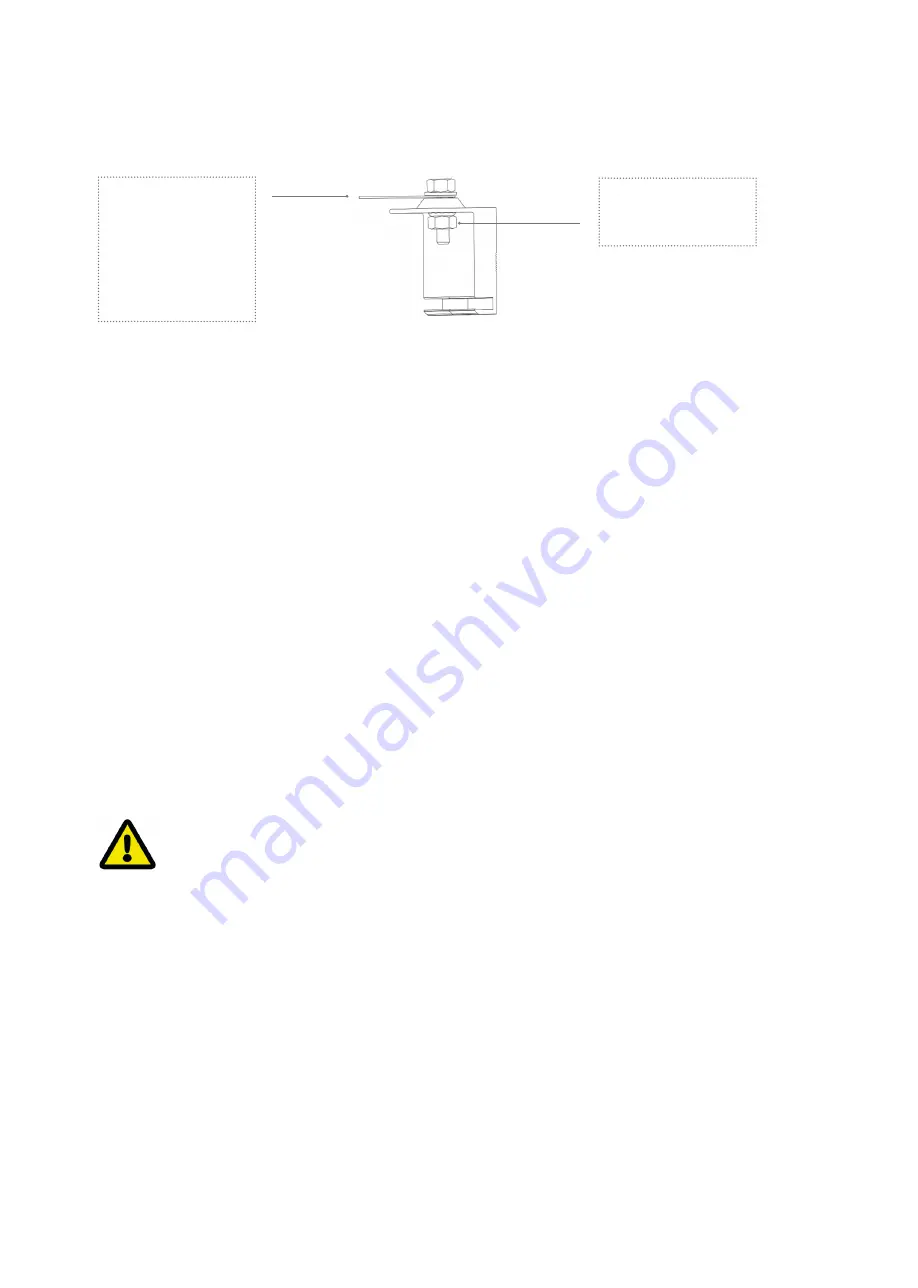

· A grounding kit containing an M5 (3/16“) SS cap bolt, an

M5 (3/16“) SS flat washer, an M5 (3/16“) SS cup washer,

and an M5 (3/16“) SS nut (with teeth) should be used to

attach copper grounding wire to a pre-drilled grounding

hole on the frame (see image above). The grounding holes

are located at the upper and lower edges of the long side

frame, close to the module short sides.

· Mounting rail designs should be such to allow easy access

to the grounding holes located on the long side of the fra-

me, in order to enable the equipment grounding function

when required.

· Place the wire between the flat washer and the cup was-

her. Ensure that the cup washer is positioned between the

frame and the wire with the concave side up to prevent

galvanic corrosion. Tighten the bolt securely using the SS

toothed nut. A wrench may be used to do this. The tigh-

tening torque is 3-7 Nm (2.2-5.2 ft-lbs).

6.0

MOUNTING INSTRUCTIONS

The applicable regulations pertaining to work

safety, accident prevention and securing the

construction site must be observed. Workers

and third party personnel shall wear or install fall arrest

equipment. Any third party need to be protected against

injuries and damages.

· The mounting design must be certified by a registered

professional engineer. The mounting design and

procedures must comply with local codes and

requirements from all relevant authorities.

· Canadian Solar Inc. does not provide mounting hardware.

· The system designer and installer are responsible for load

calculations and for proper design of support structure.

· The loads described in this manual correspond to test

loads. For installations complying with IEC 61215-2:2016

1. To fix the wire between

the flat washer and

cup washer, place the

cup washer (concave

side up) between the

frame and the wire.

2. Then tighten the bolt

using the toothed nut.

GROUNDING METHOD:

BOLT + TOOTHED NUT + CUP WASHER.

and UL 1703, a safety factor of 1.5 should be applied for

calculating the equivalent maximum authorized design

loads. Project design loads depend on construction,

applicable standards, location and local climate.

Determination of the design loads is the responsibility of

the racking suppliers and/or professional engineers. For

detailed information, please follow local structural code or

contact your professional structural engineer.

· Use appropriate corrosion-proof fastening materials. All

mounting hardware (bolts, spring washers, flat washers,

nuts) should be hot dip galvanized or stainless steel.

· Use a torque wrench for installation.

· Do not drill additional holes or modify the module frame.

Doing so will void the warranty.

WHEN CLAMPS ARE USED AS FIXING MATERIAL:

· Install and tighten the module clamps to the mounting

rails using the torque stated by the mounting hardware

manufacturer. System designer and installer are

responsible for load calculations and for proper design

of support structure. It is recommended to use a torque

wrench for installation. Tightening torques should

respectively be within 17-23 Nm (12.5-17.0 ft-lb) for

M8x1.25-Grade8.8 (5/16”-18 Grade B7) galvanized or A2-

70 stainless steel coarse thread bolts, depending on bolt

class. The yield strength of bolt and nut should not be less

than 450 MPa.

· Clamp material should be anodized aluminum alloy or

steel of appropriate grade. For frameless module used

clamps, one buffer rubber material (Recommended

material is EPDM) must be added between the clamp and

the glass.

· Clamp positions are of crucial importance for the reliability

of the installation, the clamp centerline must only be

positioned within the authorized position ranges indicated

below, depending on the configuration and load.