CPS-EP2000(R2) MANUAL

Camtec Power Supplies GmbH - Gewerbestrasse 30 - DE-76327 Pfinztal / Germany

P.8/19 (01/2018.01.1)

Tel. +49 (721) 46596 - 0 Fax +49 (721) 46596 - 77

www.camtec-gmbh.com

-

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

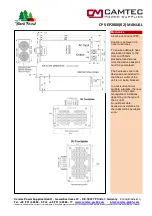

LED Operating Signal

CV/OVP CV Constant Voltage Mode LED lights Green

OVP Overvoltage maloperation or interference voltage LED lights Red

CC/OCP CC Constant Current Mode LED lights Yellow

(1)

OCP Over Current Protection LED lights Red

TA/OT

TA Temperature Alarm LED lights Yellow, warning temperature shutdown pending

(1)

OT Over Temperature Shutdown LED lights Red

INH/FF

INH Inhibit (Interlock) Shutdown LED lights Yellow

FF Fan Failure LED lights Red

SD/SB

SD Shutdown LED lights Yellow

SB Standby LED lights Red

(1)

(1)

Not available for EP-series

Configuration of the Current Share Bus (CS)

Mode

S11

S12

CS active

0

CS non-active

1

Warning!

CS (Current Share Mode) only applies when a current distribution must take place while parallel

operation mode. In single or parallel operation without the need of CS, always switch CS with S11 to OFF=1.

Factory set: CS non-active (S11=1)

Note that for DIGI3201 interface equipped unit settings will be made with the browser in the software.

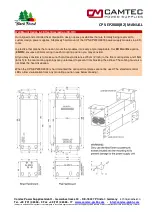

Compensation of Load Line Drop Voltage (Sense ++/--), standard operation mode

The CPS-EP power supply has a Sense Mode to compensate for the voltage drop over long load lines. The

compensation amounts to a maximum of 2V per load line. Under certain circumstances, it can be expected to

apply more complicated external interference suppression. If sense is not used, CON4 Sense +/+ and Sense -/-

shall necessarily be connected by short bridges to the power outputs (factory setup).

Sense operation: Remove the bridges between Sense +/+, Sense -/- and the power outputs. Connect the sense

lines directly to the load. It is irrelevant which of the local connections Sense +/+ and Sense -/- are applied. Pay

attention to the polarity of plus and minus of the load to prevent damage to the power supply. To avoid

interference, twist the sense lines. To reduce inductive effects, we recommend that the load lines position is

close to each other. To supply a pulsating load, the use of an electrolytic capacitor and a cermic capacitor has

proved. The internal Over Voltage Protection (OVP) of the power supply controls the DC power directly to the

DC output terminals. In case of an error the OVP acts automatically (see OVP values corresponding table).

Operating in the sense mode requires that the maximum output voltage will not be exceeded. Maximum 2V per

load lead can be compensated. The voltage drop in the load lines decreases the maximum output voltage

rating. Example of a 30V unit: if the total voltage drop in the load leads is 2V you must subtract this value from

the maximum programmable output voltage 30V – 2V = 28V maximum available voltage at the load.

The sense terminals are directly connected to the power outputs.

Lokal Sensing

Remote Sensing

(factory setup) (twisted sense lines)

WARNING! PROTECT TO MIX UP SENSE CONNECTIONS. THIS COULD CAUSE SERIOUS DAMAGE TO

THE DEVICE.