1

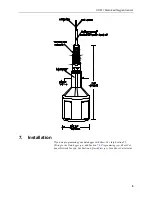

CS511 Dissolved Oxygen Sensor

1. Introduction

The CS511 is a rugged, low-maintenance sensor that is manufactured by

Sensorex. It consists of a self-polarizing galvanic cell that generates a millivolt

signal proportional to the amount of oxygen present in the measured medium

(typically water).

This manual provides information only for CRBasic dataloggers.

For retired Edlog datalogger support, see a retired manual at

www.campbellsci.com\old-manuals

. Also refer to a retired manual

if the CS511 was purchased before June 2008 and for information

on using the retired PT4-L Agitator.

2. Precautions

•

section at the front of this

manual.

•

The CS511 is a precision instrument. Please handle it with care.

•

Because the CS511 is shipped dry, electrolyte needs to be added before

(p. 7)

).

•

Letting the CS511 dry in the field shortens the life of the membrane and

sensor.

•

The sensor should be stored dry and empty. Therefore, empty the

electrolyte, rinse the sensor, and remove the membrane.

•

Replace the membrane and recalibrate the sensor before redeploying the

CS511 after it has been stored out of water or dried up in the field.

•

While cleaning, do not touch the center electrode (Section

(p. 11)

).

3. Initial Inspection

•

Upon receipt of the CS511, inspect the packaging and contents for

damage. File damage claims with the shipping company.

•

Immediately check package contents against the shipping documentation

(p. 2)

). Contact Campbell Scientific about any

discrepancies.

•

The model number and cable length are printed on a label at the

connection end of the cable. Check this information against the shipping

documents to ensure the expected product and cable length were received.

NOTE