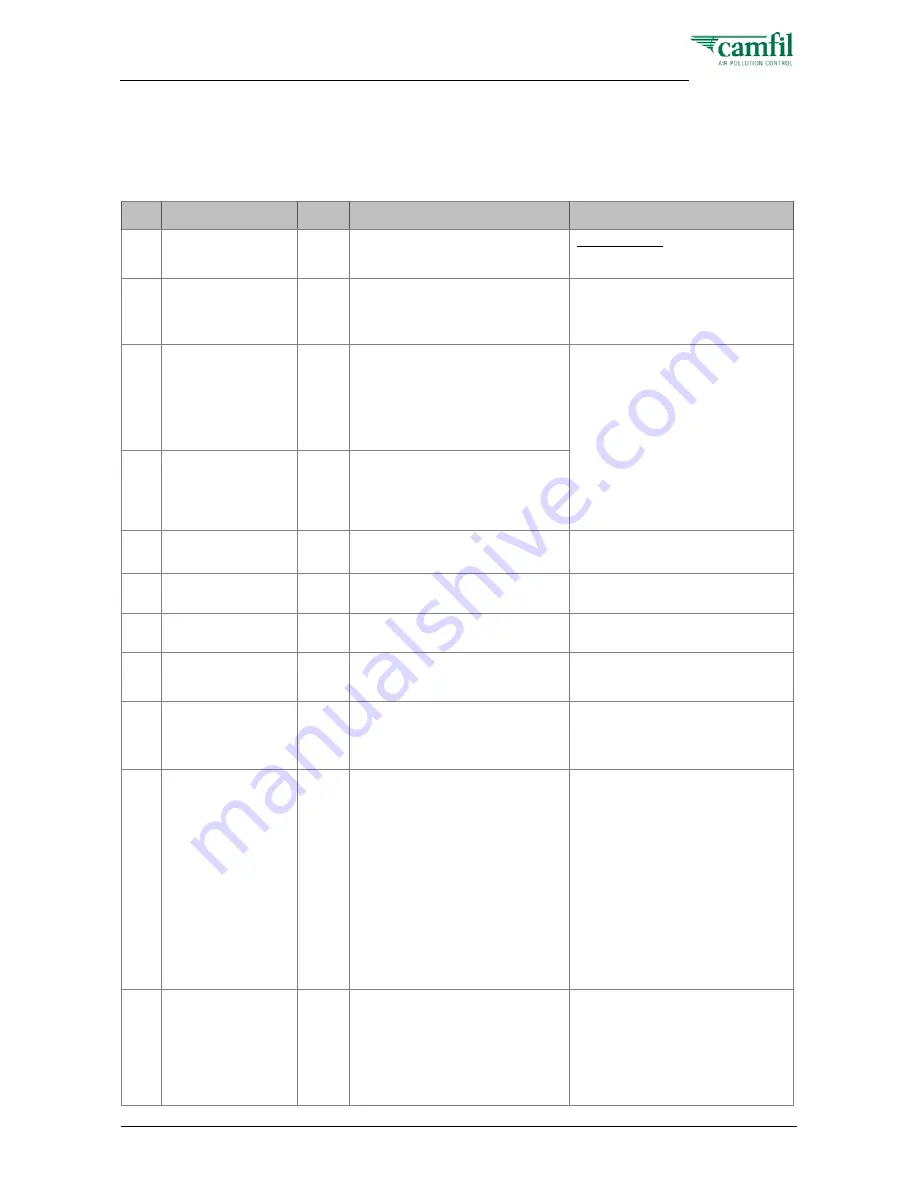

23

Maintenance

schedule

Intervals:

D

=

daily,

W

=

weekly,

M

=

monthly,

3M

=

every 3

months,

6M

=

every 6

months,

Y

=

yearly

Item

Maintenance

point

Interval

Type

of

check/maintenance

task

Comments

1

Wet

scrubber

Before

starting

cleaning

work,

drain

or

pump

out

the

content

of

the

wa

‐

ter

trap.

1.1

Air

inlet

area

W

CLEANING:

1.

Remove

deposits

of

dirt

in

the

vicinity

of

the

air

inlet

using

a

high

‐

pressure

cleaner.

Access

via

the

lower

maintenance

door

1.2

Suction

pipe/funnel

W

CLEANING:

2.

Remove

deposits

of

dirt

on

the

inside

and

outside

of

the

suc

‐

tion

pipe

and

below

the

suction

pipe

funnel.

3.

Clean

the

walls

of

the

scrubber

using

a

high

‐

pressure

cleaner.

Access

via

the

lower

maintenance

door

Separated

dust

forms

a

growing

layer

of

dirt

in

the

wet

and

dry

zones.

If

prompt

action

is

taken,

these

de

‐

posits

can

be

brushed

or

sprayed

off;

later

on

they

can

only

be

scraped

off

with

a

scraper.

1.3

Separation

zone

W

CLEANING:

4.

Remove

any

deposits

of

dirt

on

the

motor

chamber,

blade

cage,

and

walls

of

the

scrubber

with

a

high

‐

pressure

cleaner.

1.4

Motor

ventilation

lines

M

VISUAL

INSPECTION:

5.

Check

the

state

of

the

collar.

IF

NECESSARY:

1.

Replace

the

collar.

1.5

Water

return

hose

M

VISUAL

INSPECTION:

2.

Check

the

state

of

the

hose.

IF

NECESSARY:

3.

Replace

the

hose.

1.6

Water

return

pipe

(for

size

7)

M

CLEANING:

4.

Remove

any

dirt

in

the

pipe.

The

lid

must

be

removed

to

enable

cleaning.

2

Integrated

fan

2.1

Entire

fan

W

VISUAL

INSPECTION:

1.

Check

for

operating

noises;

make

sure

it

is

running

smooth

‐

ly.

IF

NECESSARY:

2.

Service

it;

rectify

faults.

2.2

Fan

impeller

W

VISUAL

INSPECTION:

3.

Completely

remove

any

depos

‐

its

of

dirt

on

the

impeller.

4.

Check

the

impeller

and

check

for

changes

(cracks,

geometric

changes,

balance,

and

wear).

Access

via

the

upper

maintenance

door

If

imbalance

is

still

present

following

impeller

cleaning,

the

impeller

must

be

rebalanced.

The

check

can

be

made

by

means

of

a

non

‐

destructive

crack

test,

for

ex

‐

ample.

An

impeller

inspection

is

required

immediately

if:

‐

The

permitted

limit

values

are

ex

‐

ceeded

‐

Changes

to

running

noise

occur

2.3

Fan

motor

W

ACOUSTIC

CHECK:

5.

Check

for

operating

noises;

make

sure

it

is

running

smooth

‐

ly.

This

check

can

only

be

made

during

ongoing

operations.

VISUAL

INSPECTION:

6.

Check

the

motor

mounting.

This

check

must

be

carried

out

when

the

system

is

at

a

standstill.

Check

this

by

shaking

the

impeller.