1 ÷ 2

p.

14

- M

an

u

al

FA

0

1

2

7

4

-E

N

- 1

1/

2

0

18 - © C

A

M

E S

.p.

A

. - T

h

e c

onte

nts of th

is

m

an

u

al

m

ay c

h

an

g

e, at a

ny ti

m

e, a

n

d w

ith

ou

t n

oti

ce

. O

rig

in

al

in

str

u

cti

on

s

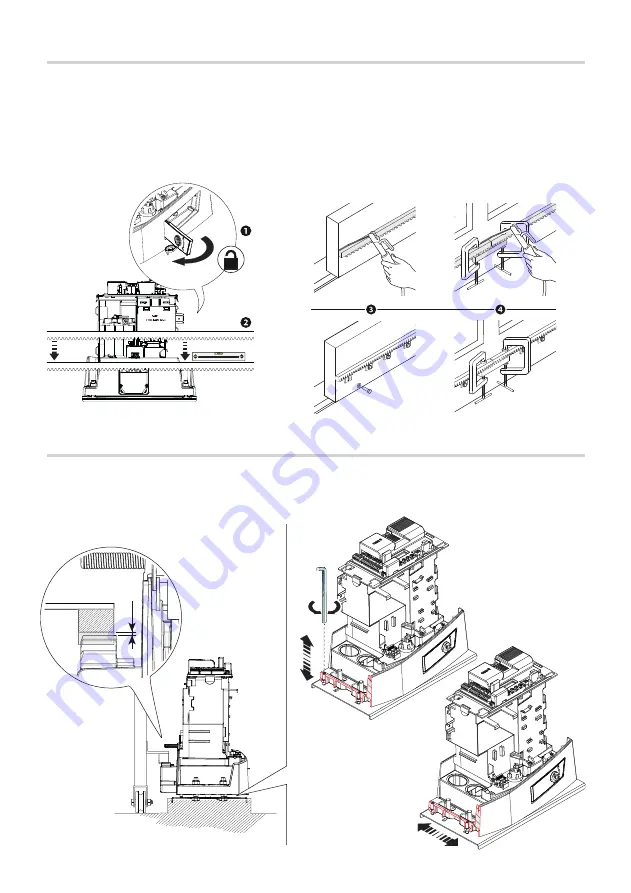

Fastening the rack

If the rack is already set up, the next step should be to adjust the rack-and-pinion coupling distance,

otherwise, fasten it:

- release the operator

;

- rest the rack above the operator pinion

;

- either weld or fasten the rack along the entire length of the gate

.

To assemble the rack modules, use an extra piece and rest it under the joint, then fasten it using two

clamps.

Adjusting the pinion-rack coupling

Manually open and close the gate and adjust the pinion-rack coupling distance using the threaded feet (vertical

adjustment) and the holes (horizontal adjustment).

The weight of the gate must not bear down upon the operator

Summary of Contents for BKV Series

Page 2: ......