User guide

R4000

MOBILE AIR HANDLING UNIT

Version: 2.4

Update: 06/2019

Page 11 / 21

•

The “Physical Configuration” is factory

-set according to your usage (mobile, fixed, temperature and

pressure cascades, optional additional sensors and probes, etc.). You can only access this level and

alter the settings if you are logged in as administrator (“ADMIN”).

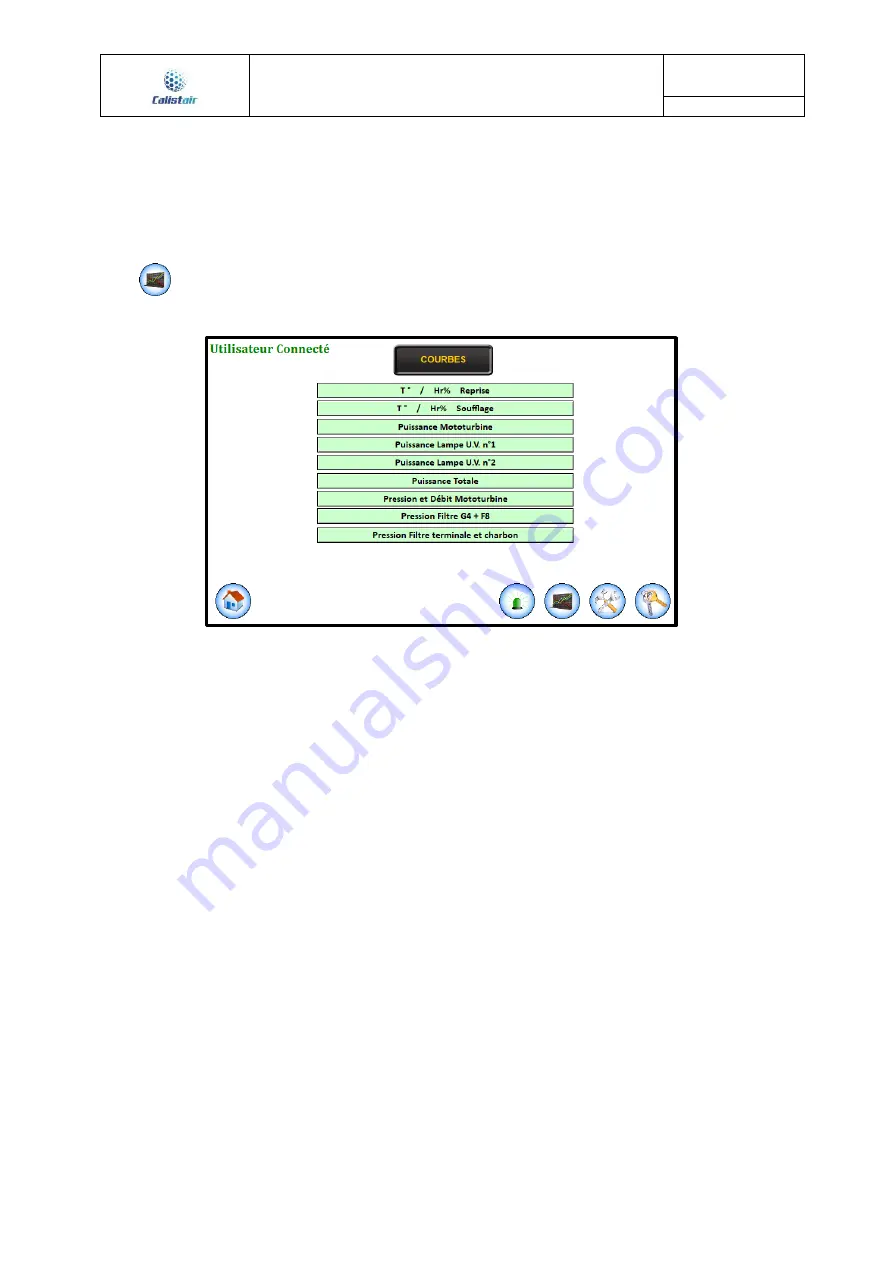

2.2.1.3

Traceability

•

To go to the R4000 traceability screen (graphs showing performance over time) directly, click on the

icon then on the criterion you want to view.

Figure 10: standards traceability criteria

•

Traceability criteria are indicated in Figure 10. These are basic criteria to be found on all mobile

R4000 units. The measurements of the temperature and humidity made at the inlet (also called

“return”) and at the outlet (also called “supply”) of the air, consumed power of the fan (motorised

impeller) and the UV bulb stages (stages 1 and 2) the pressure and air flow of the fan and the

pressure losses of the various filters can thus be monitored. Other criteria can be added and the

related sensors can be managed by the PLC such as temperature and humidity on the supply air,

the air quality monitoring sensors (CO

2

, VOC, specific gas), differential pressure probes in the rooms,

a sensor measuring the particulate concentration for monitoring ISO class, etc.

•

To view how these criteria develop over time, simply click on one of the criteria. E.g. by clicking on

“

Motorised impeller pressure and flow rate

”

, it is possible to monitor the flow rate graph for the air

treated by the R4000 and thus see when the machine stopped working for example. It is then

possible to zoom in or out on a desired period, move around the time scale, save the log, etc.