CALIFORNIA ACCENT LIGHTING, INC.

2820 E. Gretta Lane, Anaheim, CA 92806

ph. 800.921.CALI (2254) | fx. 714.535.7902 | [email protected] | calilighting.com

© CALI. All rights reserved. CALI reserves the right to make changes or withdraw specifications without prior notice.

1 / 29 / 2021 / Rev 2

Page 4 of 16

ALS

500T-RMW-TB

INSTALLATION INSTRUCTIONS

Mounting (Hanging Bracket Assembly ) 1 of 2

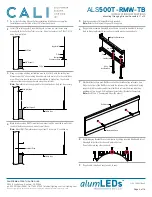

Countersink Screw

Rail Bracket

Hex Nut

8-32 x 2”

Hex Head Bolt

Lock Washer

Slot

Hanging Bracket Arm

Do not install ceiling tiles until after installation of luminaires is complete.

Installation area must have at least 10” of overhead space.

1

Determine number of Hanging Brackets required.

Note:

Refer to the diagrams on page 10 as a guide.

5

If applicable, assemble Hanging Bracket Arms. Insert Hex Head Bolts through

slots on Hanging Bracket Arms and secure with washers and hex nuts.

6

Mark locations where each Rail Bracket will be installed along reference line.

Align the bottom of the Rail Bracket with the reference line and pre-drill using

proper drill bit for surface and screw size. Each rail must be mounted with a

minimum of two screws. Drill additional holes in Rail Brackets if necessary.

Note:

Use 8/32 x 2” Countersink Screw (By others)

7

If applicable, install end caps to ends of runs.

9

Install T-Bar ceiling grid. Assemble the grid so there is a continuous edge

around grid for the Ceiling Trim to rest on. Hang the center of the T-Bar 7-5/16”

away from wall stud.

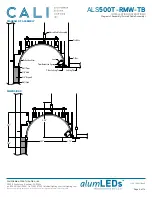

2

Hang or cut drywall along installation area so it is flush with the ceiling line.

Measure exactly 4” above ceiling line and mark each wall stud in the installation

area. Use a laser level to ensure accurate relation to ceiling line, then draw a

reference line connecting each mark along the wall studs.

Note:

Drywallers must hang drywall to the specifications. Only cut if necessary.

3

Mark locations along Wall Trim extrusion where it will be mounted to wall studs,

then drill holes as needed and mount to wall studs.

Note:

Mount Wall Trim extrusion using at least 1 screw per 2’, rounded up.

4

7-5/16”

5/8” Drywall

T-Bar

Support Wire

Wall Stud

Maintain

Continuous Edge

Ceiling Line

Mark Wall Stud

4”

Top of drywall

Mount Wall Trim

Ceiling Line

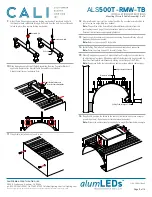

Install Hanging Bracket Arms to luminaire by sliding inverted Hex Head Bolts of

Hanging Bracket into the channels pictured below.

Do not slide into any other channels.

8