CALIFORNIA ACCENT LIGHTING, INC.

2820 E. Gretta Lane, Anaheim, CA 92806

ph. 800.921.CALI (2254) | fx. 714.535.7902 | [email protected] | calilighting.com

© CALI. All rights reserved. CALI reserves the right to make changes or withdraw specifications without prior notice.

1 / 29 / 2021 / Rev 2

Page 14 of 16

ALS

500T-RMW-TB

INSTALLATION INSTRUCTIONS

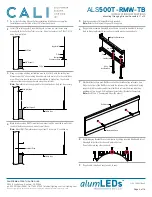

Installing Reflective Film (ALS500T-RMW-RF-98)

Second, insert edge of film

into wall-side gap between

the wall trim and extrusion.

First, insert edge of film into the

gap between lens and extrusion.

Do not cover lens with film.

Lens

Extrusion

Wall Trim

1

2

• Follow the below diagrams and steps if applicable to your installation.

• Only install Reflective Film after all other installation requirements are

complete. Lighting must be tested and in working order, and wall must be

mudded, painted, and completely dry before beginning.

• Reflective Film requires a minimum of two people to ensure a secure and

correct installation.

• Use a puller stand to prevent damage to the film while installing.

• Installers must wear gloves while handling Reflective Film.

• The Reflective Film is two-sided. Place the textured side facing downward.

The smooth side should only be facing upward.

INSTALLATION GUIDELINES

• Stable in humid environments

• Anti-static

• Abrasion resistant

• Continuous thermal stability up to 100°C

• Compatible with the following cleaning solutions: dilute ammonia, soap

solutions, Clorox Wipes, Pine-Sol, and Formula 409

FEATURES & MAINTENANCE

SPECIFICATIONS

REFLECTANCE @ 550

NM

97.5 ± 0.8% (ASTM E1164)

L* VALUE

> 98.9 (ASTM E308)

A VALUE

-0.35 ± 0.25 (ASTM E308)

B VALUE

0.90 ± 0.30 (ASTM E308)

GLOSS (60°)

< 5.0% (ASTM D2456)

THICKNESS

205 µm ± 15 (Ono Sokki EG225)

TENSILE STRENGTH

165 MPa (ASTM D882)

DEFORMATION TEMPERATURE

130°C (JIS K7196-1991)

MELT TEMPERATURE

255°C (ASTM D3418)

UL RELATIVE THERMAL INDEX

105°C (UL746)

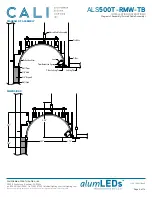

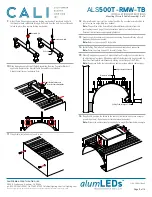

Installation Area

Reflective Film

Puller Stand

One person installs Reflective Film

according to the instructions below.

Another person feeds film from

puller stand to installer, ensuring

that film is not disturbed in the process.

Installers must wear gloves

Miter Square

Reflective Film

Rough edge

Location of new cut

Clean edge

Cut a 1’ section of Reflective Film and practice installing to get a feeling for how

it bends and forms in the luminaire. The film cannot be corrected if it is bent,

folded, wrinkled, or kinked during installation.

1

Place roll of Reflective Film onto wire puller stand. Gently pull film from roll

and feed to installer as needed. Check that the textured side is facing downward

when pulling.

3

Place beginning edge all the way to the end, so the edge of the film sits flush to

the end cap.

4

At the end of the run, estimate how much more film will be needed. Make small

cuts at the end of the film and test fit it. Repeat if necessary until the film meets

the end cap flush.

5

Check along entire run that Reflective Film is installed correctly. Ensure lens is

not covered by film and that it is securely tucked into each edge along the run.

6

If applicable, cut the end of the sheet so it has a smooth and even edge.

Tip:

Use a tool to ensure an accurate cut.

2