14

Combi

(continued)

81

Installation & Service Manual

Maximum Domestic Water Pressure

145 PSI

Domestic Water Connections

3/4" Copper

Flow Switch Setting

0.53 GPM

Basic operation

The factory installed option of the Cadet with domestic heating

capability includes a separate water circuit for the boiler water

to instantaneously and indirectly meet the demand of domestic

hot water. The domestic heating demand has priority over

space heating in this configuration. When the flow switch

closes, the DHW pump is energized and the boiler ignition

sequence begins or is switched immediately from the space

heat demand. The firing rate is now controlling to meet the

user set point of the domestic water outlet (reference FIG. 11-1

on page 63).

Operation of domestic demand in short and cyclical patterns is

met by the removal of the anti-cycling function from standard

boiler operation.

Domestic Flow Rate

(GPM)

Domestic Temperature

Rise (°F)

0.5 - 2.0

>100 degrees rise

2.5

85

3.0

70

3.5

61

4.0

53

Flow characteristics

The above data was taken at 100% boiler firing rate with a

beginning DHW temperature of 55°F.

Reference

Section 11 - Operating Information

for User

Adjustable Parameters and Default Settings.

Single-wall heat exchanger

Uniform Plumbing Code

Single-wall heat exchangers are permitted if they satisfy all

of the following requirements --

1. The heat transfer medium (boiler water) is potable

water or contains only substances which are recognized

as safe by the U.S. Food and Drug Administration.

2. The pressure of the heat transfer medium (boiler water)

is maintained less than the normal minimum operating

pressure of the potable water system.

3. The equipment is permanently labeled to indicate that

only additives recognized as safe by the FDA shall be

used in the heat transfer medium.

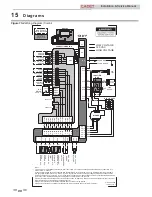

Combi DHW fittings installation

The Domestic Hot Water (DHW) fittings are factory supplied

and should be installed as follows (reference FIG. 14-1):

•

Assemble the union fitting, flow switch (tee only), and

the NPT to sweat adapter with thread sealant.

•

Connect the assembly to the brazed plate inlet DHW

fitting with the kit supplied gasket.

•

Connect the union to sweat adapter to the brazed

plate outlet DHW fitting with the remaining kit

supplied

gasket.

•

Sweat/solder the cold and hot water supply for DHW

operation.

•

Install the flow switch paddle assembly with the arrow

towards the brazed plate. DO NOT use thread

sealant.

IMG00285

UNION TO SWEAT

ADAPTER

UNION TO NPT

ADAPTER

GASKET

FLOW

SWITCH

FLOW SWITCH

TEE

FLOW ARROW

DIRECTION

NPT TO SWEAT

ADAPTER

Figure 14-1 Combi DHW Fittings Installation

The heat transfer medium (boiler

water) must be water or other nontoxic

fluid having a toxicity rating or class of

1, as listed in Clinical Toxicology of

Commercial Products, 5th edition.

The pressure of the heat transfer

medium (boiler water) must be limited

to a maximum of 50 PSIG by an

approved safety or relief valve.

Electrical

The Combi specific electrical circuits are pre-wired from the

factory and no field wiring is required. The tank sensor and

tank thermostat connections on the low voltage connection

board are the inputs for the DHW outlet water sensor and

DHW flow switch, respectively. The DHW pump is pre-wired

to the boiler’s DHW pump output, reference

Table 13-2A -

Inlet Water/System/DHW Sensor Resistance vs. Temperature

Table

on page 71 of this manual.

CAUTION

Specifications