20

20

6 Cleaning

6.5

Cleaning the Cutter

i

Note!

When cutting through the label material remains of adhesive may accumulate on the blades. If operating in

backfeed mode, such remains of adhesive may be deposited on the drive roller as well.

Clean the drive roller and the cutter blades often.

1

1

2

5

4

3

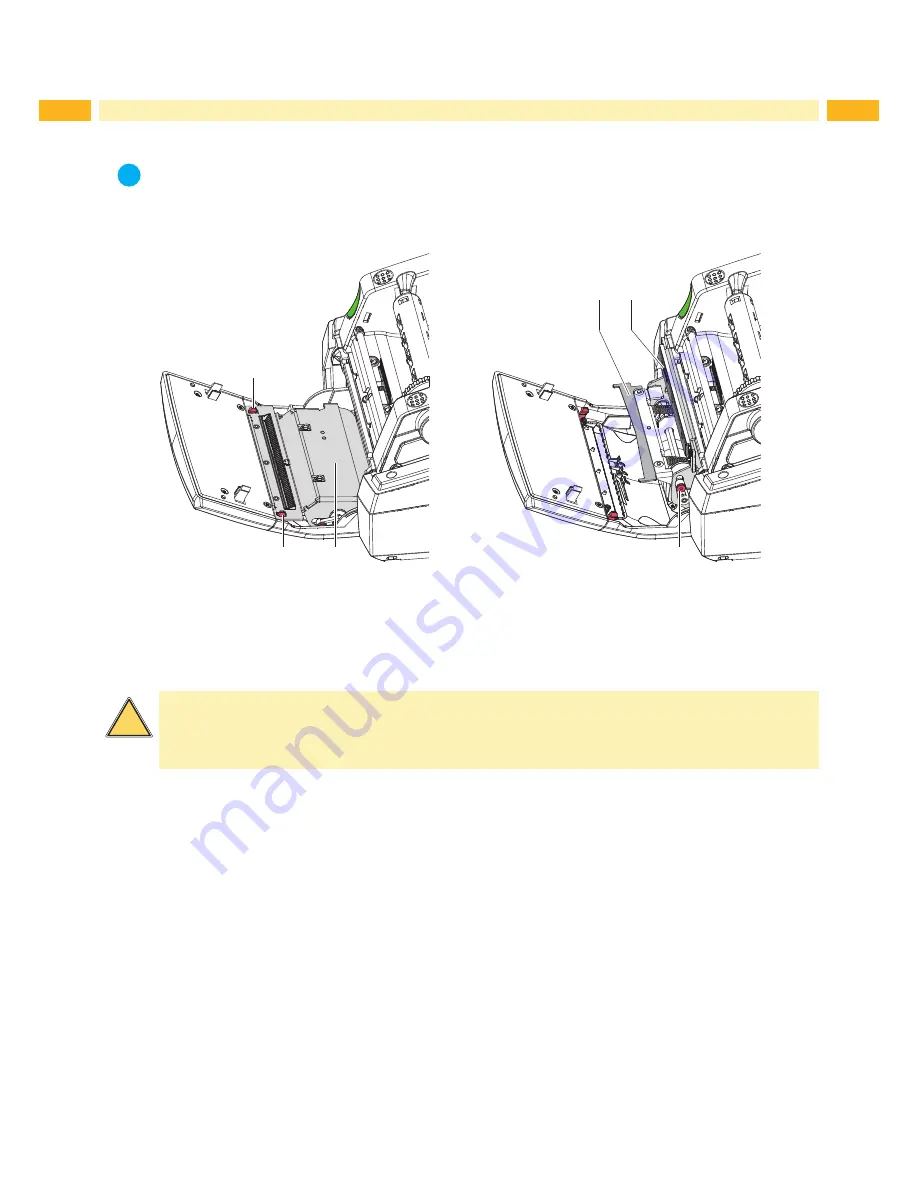

Figure 21

Cleaning the cutter

Lower the control panel

Release the cutting unit (2) via the plastic latches (1) and lift it off.

Turn the screw (5) counterclockwise using a 2.5 mm allen key and swivel the clamp with the lower blade (3) away

from the upper blade (4).

!

Warning!

Risk of cuts and bruising!

Do not touch the blade edges with bare hands.

Keep hands away from the swivel range of the lower blade.

Remove particles of dust and paper with a soft brush or a vacuum.

Remove remains of adhesive with isopropyl alcohol.

Remount in reverse order.