14

15

Important

• Before installing the operator read these instructions.

• Use of a

HYDRO

product for any application not described in this instruction manual is prohibited.

• The user must be instructed on the use of the automation system.

• The user must be consigned the instruction manual.

• All CAB products are insured against damage or injury caused by manufacturing defects under the essential

condition that the operator has the CE marking and all genuine CAB components are installed.

General Information

Hydraulic operator for swing gates, available in various versions:

HYDRO

reversible – requires an electric lock

HYDRO BA

hydraulic lock on opening stroke – requires an electric lock

HYDRO BC

hydraulic lock on closing stroke

HYDRO BAC

hydraulic lock on opening and closing stroke

HYDRO L

slow version – requires an electric lock

HYDRO PLUS slow version with extended stroke – requires an electric lock.

“Hydro BC” and “Hydro BAC” models are equipped with hydraulic lock on the opening stroke and do not require

an electric lock since the operator locks the wing shut when the motor is not in running.

Models without hydraulic lock on opening stroke (i.e. Hydro - Hydro BA.R - Hydro L - Hydro Plus) always require an

electric lock to guarantee the wing is locked shut mechanically.

All models are equipped with adjustable hydraulic slowdown on the closing stroke.

Preliminary Checks

For the gate automation to work properly, the actual gate must have the following characteristics:

- it must be robust and rigid.

- the hinges must have only limited play and provide smooth and gentle gate movements.

- the whole height of the wings must be in contact when closed.

Gate Stops

If they are not already provided, install gate stops on the opening and closing stroke limits (Fig.3) regardless of the

type of operator being installed.

The closed stop in particular is indispensable given the special characteristics of hydraulic operators. See “maintain

stop” function in the instructions for the control unit.

Installing the automation system

1 Establish the height of the automation from the ground (preferably as close to the centre of the wing as possible

and along a solid cross rail).

Remember that under the operator there is a vent hole and in certain conditions (e.g. rain or snow) it may draw

liquid into the automation. For this reason it is best not to install the operator too close to the ground.

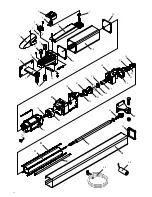

2 Weld or otherwise anchor plate P in place, see installation distances (Fig.2) and the installation diagram (Fig.5):

- remove screws V and cover C

- insert pin P in bracket P as in the figure

- lock everything in place by washer R and self-locking nut D

-

remove the vent plug VS with its gasket RS

. (see note “Vent plug”)

Observe the distances given in the tables at fig. 2, correcting the length of the plate if necessary. In some cases

a recess may have to be made in the post.

It is essential that the installation distances are respected for the operator to work correctly.

With reference to the installation tables note that:

For the wing to open 90°:

A+B must be equal to the operator stroke

For the wing to open more than 90°:

A+B must be less than the operator stroke.

Keep the length differences within 40mm. Over this difference the wing movement becomes uneven. When reduc-

ing lengths A and B , increase the wing speed.

Comply with all statutory regulations.

3 Release the operator (see section “manual gate operation”)

4 Slide out the ram shaft completely and then slide back in by approx. 10 mm. Lock the operator in place.

Always leave a safety overrun of 10 mm in both the closing and opening strokes. The stroke length given in the

technical data and installation tables has already been reduced by the necessary 20 mm.

Summary of Contents for HYDRO

Page 36: ...CL8542500 Rev 07 05 00 ...