23

cab Produkttechnik GmbH & Co KG

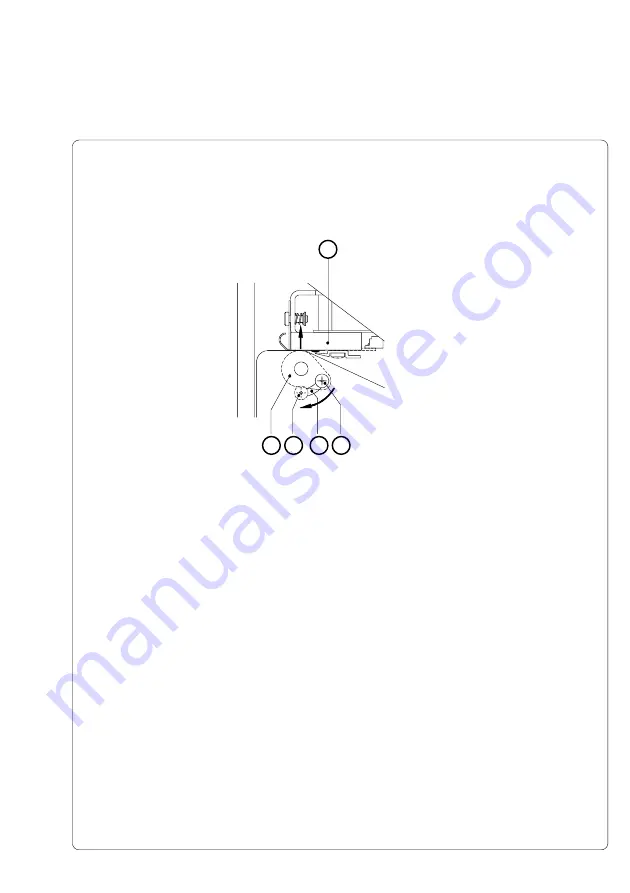

When printing narrow label stock (width less than 2.5" or 60 mm), it is possible

that the printhead will come into direct contact with the drive roller. This will

lead to premature wear on the printhead. In addition, the printhead will be at a

slight angle to the label, and this uneven pressure may result in an inconsistent

image density from one edge of the label to the other. To correct this problem,

the printhead support (

4

) should be adjusted.

Adjust the printhead support as follows:

1. Loosen the locking screw (

2

).

2. Move the locking screw (

2

) as required within the adjustment slot (

3

). This

will cause the cam shaped printhead support (

4

) to rotate, in effect,

providing a higher or lower base on which the printhead mounting (

1

) rests.

3. When using wide labels, start with a setting of "2a"; this places the

printhead support at its' lowest position, providing the most complete

contact of the printhead to the drive roller along the entire width. When

using very narrow labels, a setting of "2b" is recommended; this places the

printhead support at its' highest position, reducing contact of the printhead

with the drive roller at the outside edge.

At the adjustment criterion, check the quality of the print image.

4. Retighten the locking screw (

2

).

7. Adjustments Concerning the Labels

Adjustment of the Printhead Support

1

4 2b 3 2a

Figure 7 a Adjustment of the Printhead Support