UK

27

13.6

Spare Parts List BWT PERMAQ

®

Pro 2000

Item

No.

P&I

id

BWT PERMAQ

®

Pro 2010-2080

Recom-

mended

spare parts

Article No.

Recommended

replacement

frequency

1

V2

¾” Needle valve (Recirculation)

1

200731006

2

PS1 Pressure switch 0,5 Bar

1

452550005

3A

Y1

¾” Solenoid valve (Pro 2010-2040)

1

200752006

3B

Y1

1” Solenoid valve (Pro 2060-2080)

1

200752010

4

PI1

Manometer 0-40 Bar

1

452266000

5

V5

¾” Ball valve (control valve)

1

200742006

6

V3

¾" Needle valve (outlet valve)

1

200731006

7A

P1

High-pressure pump (Pro 2010-2020)

454101225

7B

P1

High-pressure pump (Pro 2030)

454102226

7C

P1

High-pressure pump (Pro 2040-2080)

454102222

8A

FI1

Flow meter, Permeate (Pro 2010-2040)

453010325

8B

FI1

Flow meter, Permeate (Pro 2030-2080)

453010340

9

FI2

Flow meter, Concentrate (Pro 2030-2080)

451405100

10A

Control box complete (Pro 2010-2020)

451404812

10B

Control box complete (Pro 2030-2080)

451404813

11

Control PCB complete

12

V4

Test valve (water hardness test)

200721020

13

Quick fitting 14 mm, elbow

1

454090014

3 years

14

Quick fitting 14 mm x ½”, Base

454065014

3 years

15

V7

¾” Ball valve

Membrane/pressure vessel

16

Pressure vessel

451404079

17

Membrane

1-4

451404960

*

18

U-lock

451404090

19

V-Cup seal for membrane

2-8

451404208

20A

End plate

1

451404113

3-5 years

20B

End plate

1

451404112

3-5 years

21

O-ring outside (large)

8-32

451404211

2 years

22

O-ring inside (small)

8-32

451404215

2 years

23

¾” Pressure hose, L=400 mm

1

451404177

24

¾” Pressure hose, L=130 mm

1

451404178

25A

¾” Pressure hose, L=480 mm

(Pro 2010-2020)

1

451404174

25B

¾” Pressure hose, L=320 mm

(Pro 2030-2080)

1

451404165

Spare parts for options

Sensor (conductivity meter)

452536007

QIS1

Conductivity meter

-

452525000

14 mm hose

454001014

3 years

P5

Antiscalant pump

100513000

FS5 Antiscalant flow switch

110844420

Y2

¾” Solenoid valve, (Pro 2010-2040)

200752006

Y3

¾” Solenoid valve, (Pro 2010-2040)

200752008

Y2

1” Solenoid valve, (Pro 2060-2080)

200752010

Y3

1” Solenoid valve, (Pro 2060-2080)

200752012

* Contact your local BWT dealer for detailed information.

Summary of Contents for PERMAQ PRO 2000

Page 2: ...UK 2...

Page 11: ...UK 11 Alarm Transport pump 9 2 4 Indication Level low 9 2 5...

Page 19: ...UK 19 13 1 P I Diagram...

Page 20: ...UK 20 13 2 Layout Drawings...

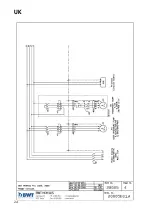

Page 21: ...UK 21 13 3 Wiring Diagram...

Page 22: ...UK 22...

Page 23: ...UK 23...

Page 24: ...UK 24...

Page 28: ...UK 28 13 7 Spare Parts Drawing...