1300 720 299

Ball Valve and Tubing Installation:

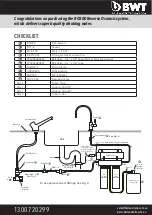

FIGURE C

Final tubing connections and start up:

4

5

The grey inlet adaptor provides a simple, easy connection between the cold water shut-off and the cold water line.

1.

Shut-off the cold water supply by using the existing shut-off valve or stop cock, located under your sink. Leave the water

supply off until installation is complete.

2.

After shutting off the valve, turn on kitchen tap on the cold water side, this will relieve any excess water and ensure water is

off.

3.

Using an adjustable wrench, disconnect the 1/2” braided SS hose line from the cold water shut-off valve.

4.

Connect the grey inlet adaptor to the male thread on the cold water shut-off valve. Do not overtighten

5.

Reconnect the braided SS braided hose to male thread of the grey adaptor.

6.

Connect a length of the 1/4” white tubing between the grey adaptor and the inlet of the R.O. unit.

7.

Cut into this line the small quick connect ball valve (turned off) and the pressure limiting valve (PLV).

1.

Tubing should follow contour of the cabinets.

2.

Cut tubing to correct length using tube cutter provided.

3.

Make sure there are no crimps in the tubing.

4.

Keep tubing from the R.O. unit to the tank and faucet as short as possible for good flow.

5.

Connect blue tube from R.O. to tap connector (or point of use)

6.

Leave the yellow tube to flow to atmosphere into a small bucket – so all air is purged through the system.

The isolating valve or stop cock of the mains cold water line can be turned slowly on. The main faucet on the sink will

flow and can now be turned off. The ball valve in the white plastic 1/4” tube should be turned on (tap to run in line with

tube, this is the ON position). Check for leaks. Water will now fill the RO300 and eventually water will slowly discharge

from the yellow tube. When water appears from the yellow tube, fit the yellow tube into the ball valve connected to the

top of the pressure tank. The tank will take some time to fill. When the tank is full, water will stop discharging to the

drain. When the faucet is open – or point of use dispenser is used, the RO water will flow from the tank under pressure.

Grey adaptor

Water Flow

Cold water

Stop valve

Cold

water

Inlet

S.S. braided hose

Figure C

www.bwtaustralia.com.au