INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 16 of 66

7505-M001-3_B

NAV11N - NAV11NT

NAV11EI - NAV11TEI

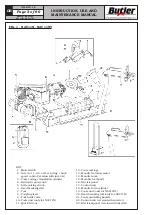

11.0 CONTROLS

11.1 Control device (valid for NAV11N and

NAV11NT models)

The control (handle control) can be moved according

to the positioning necessities of the operator.

MAKE SURE THERE ARE NO PER-

SONS OR OBJECTS HIDDEN TO

THE OPERATOR VISUAL FIELD

BY THE WHEEL SIDE PLAY (ESPE-

CIALLY IN CASE OF WHEELS WITH

LARGE DIMENSIONS).

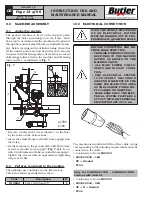

The control (

Fig. 9

) consists of:

•

“A” lower selector

(with protection) three-positions

control for opening and closing of wheel holder man-

drel: a central “firm” position for stop of mandrel

opening/closing movement and two “hold activation”

positions for mandrel jaws opening/closing;

•

“B” lever

three-positions control for tools holder

carriage translation: a central “firm” position for

translation stop and two “hold activation” positions

for carriage supporting translation towards the man-

drel and return;

•

“C” lever

three-positions control for vertical trans-

lation of mandrel arm: central “firm” position for

movement stop and two “hold activation” positions

for arm up and down translation;

•

“D” small lever

control for mandrel clockwise/anti-

clockwise rotation;

A

B

C

B

C

D

Fig.

_

9

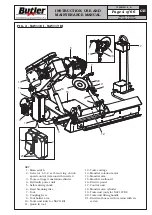

11.2 Control device (only for NAV11N and

NAV11NT models with VARGNAV11ND

version with inverter)

This control device consists of 2 units:

- control unit on machine,

- ground control unit.

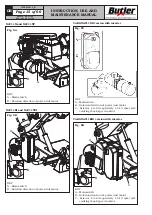

The control unit on machine (see

Fig. 10A

) can be

moved according to the positioning necessities of the

operator.

MAKE SURE THERE ARE NO PER-

SONS OR OBJECTS HIDDEN TO

THE OPERATOR VISUAL FIELD

BY THE WHEEL SIDE PLAY (ESPE-

CIALLY IN CASE OF WHEELS WITH

LARGE DIMENSIONS).

The control (

Fig. 10A

) consists of:

•

“A” lower selector

(with protection) three-positions

control for opening and closing of wheel holder man-

drel: a central “firm” position for stop of mandrel

opening/closing movement and two “hold activation”

positions for mandrel jaws opening/closing;

•

“B” lever

three-positions control for tools holder

carriage translation: a central “firm” position for

translation stop and two “hold activation” positions

for carriage supporting translation towards the man-

drel and return;

•

“C” lever

three-positions control for vertical trans-

lation of mandrel arm: central “firm” position for

movement stop and two “hold activation” positions

for arm up and down translation;

•

“D” selector

, three-positions, for mandrel rotation

speed: position “0” for movement stop, position “1”

for low speed and position “2” for high speed.

Fig. 10A