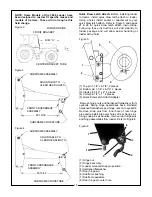

LOADER MOUNTED CONTROL VALVE

EQUIPPED WITH 2 OR 3 CONTROL HANDLES

OR TRACTOR REMOTE VALVE EQUIPPED WITH

2 OR 3 CONTROL HANDLES

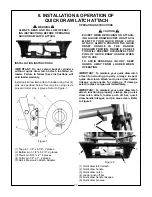

If your loader utilizes a loader mounted control valve

equipped with 2 or 3 control handles or tractor

remote valve equipped with 2 or 3 control handles, it

will function as described in Figure 3.

Lift Cylinder Circuit

Pull the handle

back to raise unit

Push the handle

forward to lower unit

Push handle full forward

to activate float position

Attachment Cylinder Circuit

Pull the handle

back to roll

back attachment

Push the handle

forward to

dump attachment

3rd Cylinder (optional) Circuit

Pull the handle

back to open

assembly

Push the handle

forward to close

assembly

Figure 3

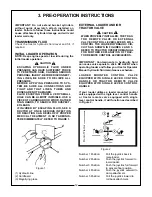

NEUTRAL POSITION

The loader external valve provided by Bush Hog has

a “neutral position” which prevents movement of the

loader or attachment. When the control handle is

manually released from the work position, the valve

spool will return to the neutral position.

FLOAT POSITION

The loader external valve provided by Bush Hog has

a “float position” incorporated into the lift cylinder cir-

cuit which allows the loader to float. This float fea-

ture is important for satisfactory operation when

scraping, sweeping, leveling, or any job where it is

necessary to follow the contour of the surface. To

activate the float position, lower the bucket or

attachment and push the control handle all the way

forward into detent. The valve will stay in float detent

position until the operator manually pulls the control

handle out of detent position to deactivate float.

INITIAL LOADER OPERATION

Before operating the loader, fully raise and lower the

boom two or three times. Then raise the loader

bucket approximately four (4) feet above the ground

and cycle the bucket cylinders two or three times.

Lower the bucket or attachment to the ground.

Check the tractor hydraulic fluid level and fill as

required. Refer to the tractor Operator Manual for

the proper hydraulic fluid and the correct hydraulic

fluid level.

CAUTION

BEFORE LEAVING THE TRACTOR SEAT,

LOWER ATTACHMENT OR LOADER BOOM

TO GROUND, STOP ENGINE, LOCK

BRAKES, RELIEVE HYDRAULIC PRESSURE,

AND REMOVE KEY.

IMPORTANT: Always keep the cylinders in a

retracted position when the loader is not in use

to guard against rust and contamination which

may cause damage to the cylinder rods and

hydraulic system.

REMOVING AIR FROM HYDRAULIC SYSTEM

Repeat raising and lowering the loader boom and

bucket operations until all the air is removed from

the system and the system responds properly.

HOSE IDENTIFICATION

Check if loader functions as shown and described in

Figures 2 and 3. Then install colored nylon ties, one

color per each circuit. Locate nylon ties so one is

attached to male side of quick coupler and one is

attached to female side of quick coupler. This will

allow easy identification of loader circuits when

mounting and dismounting loader.

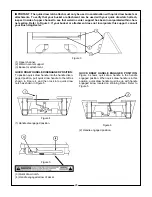

BUCKET LEVEL INDICATOR

BLI (bucket level indicator) rod has been preassem-

bled to loader linkage pin at the factory.

BLI (bucket level indicator) must be adjusted during

initial loader set up. Adjust the BLI as follows:

Position the bucket level on the ground. Loosen the

BLI clamp holding the BLI tube, and align the BLI

tube so that it is flush with end of the BLI rod, then

retighten BLI clamp. When operating loader, use the

attachment cylinder controls to align the BLI rod so

that it is flush with the end of the BLI tube. This will

inform the operator that the bucket and/or attach-

ment bottom is level with ground. Refer to Figure 4.

Figure 4

Bucket Level

Indicator

13