bühler

Allied Front-End Loader

- 24 -

P4094

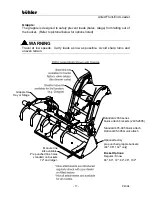

Mounting Kit:

After the initial 2 weeks or 40 hours of loader operation, and 6-month intervals

thereafter re-torque all mounting kit bolts. (See below for proper bolt torques)

Bolt Torque Chart:

(Side plate part of

mounting kit)

Mount kit bolts

Loader mount

plate

(part of mtg. kit)

Standard

Metric

ft-lbs

NM

ft-lbs

NM

ft-lbs

NM

ft-lbs

NM

ft-lbs

NM

ft-lbs

NM

ft-lbs

NM

0.25

6

7

8

11

12

16

6

3.1

4.3

7.3

9.9

10.3

14

12.1

16.5

0.313

11

15

17

23

25

33

8

7.7

10.5

17.7

24

25

34

29

40

0.375

20

27

31

42

44

60

10

15

21

35

48

49

67

59

81

0.438

32

43

49

66

70

95

12

26

36

61

83

86.2

117

103

140

0.5

49

66

76

103

106

144

14

42

58

97

132

136

185

162

220

0.563

70

95

109

148

153

207

16

64

88

147

200

210

285

250

340

0.625

97

131

150

203

212

287

18

89

121

202

275

287

390

346

470

0.75

144

195

266

360

376

509

20

126

171

287

390

405

550

486

660

0.875

166

225

430

583

606

821

22

169

230

390

530

549

745

656

890

1

250

339

644

873

909

1232

24

217

295

497

675

708

960

840

1140

1.125

354

480

795

1077

1288

1745

27

320

435

733

995

1032

1400

1239

1680

1.25

500

678

1120

1518

1817

2462

30

435

590

995

1350

1401

1900

1681

2280

1.375

655

887

1470

1992

2382

3228

33

590

800

1349

1830

1902

2580

2278

3090

1.5

870

1179

1950

2642

3161

4283

36

759

1030

1740

2360

2441

3310

2935

3980

39

988

1340

2249

3050

3163

4290

3798

5150

Torque

Torque

Torque

Torque

Torque

Torque

Torque

Bolt Size

(in.)

Grade 2 Bolts Grade 5 Bolts Grade 8 Bolts

Bolt Size

(mm)

Class 5.6

Grade 8.8

Grade 10.9

Grade 12.9

Summary of Contents for 2595

Page 1: ......

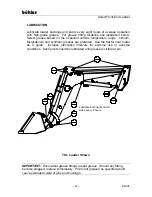

Page 4: ...b hler Allied Front End Loader 2 P4094 LOADER SPECIFICATIONS Illustration TSL shown...

Page 10: ...b hler Allied Front End Loader 8 P4094 Safety Decal Location...

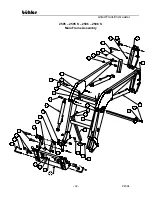

Page 34: ...b hler Allied Front End Loader 32 P4094 2595 2595 S 2596 2596 S Main Frame Assembly...

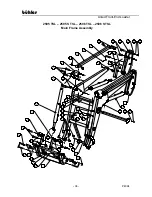

Page 36: ...b hler Allied Front End Loader 34 P4094 2595 2595 S 2596 2596 S Hydraulic Plumbing Assembly...

Page 47: ......