Page 2

The numbers assigned to the parts of our various

assemblies in our parts list are not the part numbers

used in manufacturing the part. They are identification

numbers, that when given with the trolley model number,

permit us to identify, select or manufacture and ship the

correct part needed for any trolley.

particular beam size. As a result the following procedure should

be followed:

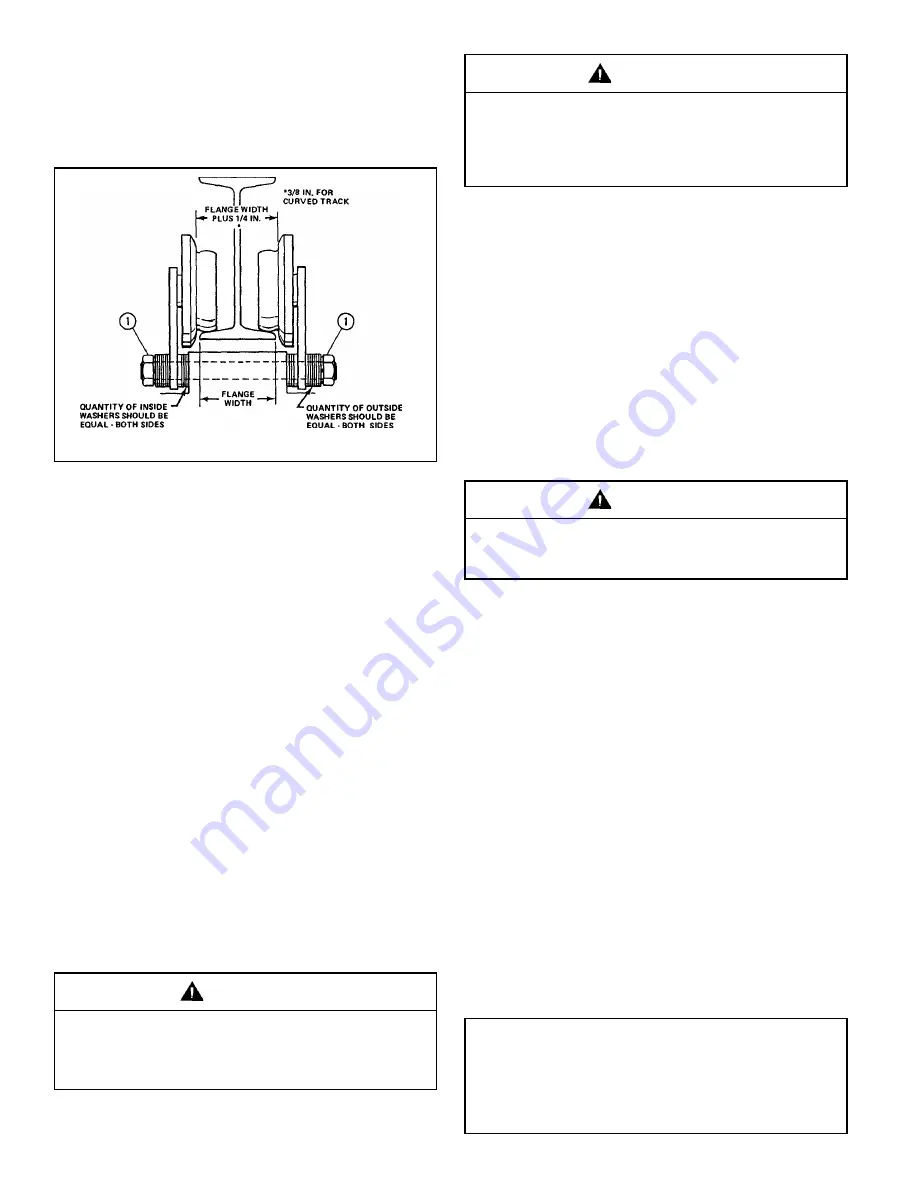

4. Measure exact width of bottom beam flange and add 1/4" to this

dimension. This is the required distance between inside faces of

wheel flanges to obtain proper operating clearance, as indicated

in Figure 2.

12207A

Figure 2. Sectional View of Trolley Showing

Proper Wheel and Washer Spacing.

5. An equal number of washers must be removed or added at

each end of lug (inside side plates) as required to obtain proper

wheel spacing determined in Step 4. When spacing is correct,

remaining spacer washers are to be installed in equal numbers

on outside ends of cross pins. Install lock-washers and tighten

hex nuts.

Note: It is important that all the spacer washers that come with

trolley be used.

SUSPENDING TROLLEY AND HOIST

1. On push type trolley models determine whether hoist is to be

suspended with frame parallel to runway beam or cross mounted

(90 degrees to beam). Refer to hoist manual for instructions on

suspension lug rotation.

2. On hand geared models the trolley is restricted to parallel

mounting on hoist frame because of the handwheel and chain.

When hoist chain container is to be used, trolley hand chain must

be placed on side opposite tail chain of hoist (where chain

container is mounted).

3. Hoist and trolley may be installed on I-beam by one of two

methods. If trolley can be slipped directly over end of beam, it

need not be partially disassembled. If this is impossible, remove

hex nuts, lock-washers, outer spacer washers and one side plate

from one side of trolley and reassemble on beam.

OPERATING PRECAUTIONS

DO NOT load trolley beyond rated load.

DO NOT subject trolley to side loads. Always center trolley

over load when hoisting.

DO NOT ram trolley into end stops, other trolleys, or any

obstruction on beam. Improper and careless operation can

result in a hazardous condition for operator and load.

ALWAYS be sure load is clear of obstruction before traversing

load and trolley.

DO NOT stand and DO NOT cause or allow others to stand or

get under any load the trolley is supporting. DO keep clear,

and make sure others keep clear, of any load the trolley is

supporting.

MAINTENANCE AND LUBRICATION

1. BUDGIT Heavy Duty Rigid Mount Trolleys are built to give long

service, but should be inspected periodically for evidence of

damage or wear, particularly when subjected to unusual severe

operating conditions.

2. Lubrication requirements:

a. Wheel bearings are permanently lubricated and require no

additional lubricant.

b. Drive wheel gears are to be lubricated with an open type

gear grease which is heavy, plastic, extreme pressure and

tacky; such as MOBILTAC 325 NC or equal.

REPLACEMENT PARTS

The following parts lists and illustrations cover standard model

BUDGIT Heavy Duty Rigid Mount Trolleys. Typical units are used

as the basis for the exploded parts illustrations; therefore certain

variations may occur from the parts information given. For this

reason always give the catalog number and model number .

Pins referred to in some column headings are trolley suspension

pins.

In all cases, after trolley and hoist have been installed on

I-beam, make sure a suitable stop is secured to each end of

beam to prevent trolley rolling off. Make certain lock-washers

are in place on cross pins and hex nuts are tight.

CAUTION

If trolley is mounted on an open-end beam, end stops

must be installed to prevent trolley from running off the

end of the beam, resulting in injury to operator and others,

including danger to life and limb and damages to load

and other property.

WARNING

These trolleys are not designed nor intended to be used

to support or transport people or for supporting or

transporting loads over people.

WARNING

Recheck clearance dimensions between wheel flanges and

beam flanges.