9

Be sure to unplug and inspect the unit before proceeding with these steps. Start with problem 1, then problem 2 and so on.

Table 6 – Troubleshooting

Problem:

Possible causes:

You should try this:

1. Unit does not

work.

S

Erratic operation of the electronic

circuit.

S

Unplug the unit. Wait for 30 seconds. Plug it back in.

S

The breaker in the electrical panel

may be tripped.

S

Reset breaker. If it trips again, unplug the unit and call an electrician.

S

The door switch may be defective

S

Using a multimeter, check for power across the switch (the door switch

must be pushed in for this test). If there is no power, replace the switch.

S

The circuit board may be

defective.

S

Jump “B” and “G” (BLACK and GREEN). If unit

switches to high speed, remove the wall control

and test it right beside the unit using another

shorter wire. If the wall control works there, change

the wire. If it does not, change the wall control.

S

The fan motor may be defective.

S

Unplug the unit and disconnect the fan motor (4 wires). Supply 120 V

directly to the GREY and ORANGE wires of the fan motor. Replace the

motor if not working.

S

The 9--pin connector may have a

loose connection.

S

Unplug the unit and check to make sure all the crimp connections are

sound. Check the fan motor and the damper actuator connections as well.

2. The damper

actuator does not

work.

S

The 9--pin connector may have a

loose connection.

S

Unplug the unit and check to make sure all the crimp connections are

secured. Check the damper actuator connections as well.

S

The damper actuator may be

defective.

S

Feed 120 V directly to the damper actuator. If the problem persists,

replace the damper actuator.

S

The circuit board may be

defective.

S

Replace the circuit board if the problem is not solved by the above.

3. The wall control

will not work.

S

The wire in the wall OR the wall

control may be defective.

S

Remove the wall control and test it right beside the unit using another

shorter wire. If the wall control works there, change the wire. If it does

not, change the wall control.

S

The wires may be in reverse

position.

S

Ensure that the color coded wires have been connected to their

appropriate places.

S

The wires may be broken.

S

Inspect every wire and replace any that are damaged.

S

There may be a short--circuit.

S

With the help of a multimeter, check for continuity.

4. The 20--minute

lighted push--

button switch

doesn’t work OR

its indicator light

doesn’t stay on.

S

The switch may be defective.

S

The wires may be defective OR

may not be connected properly.

S

Jump the OL and OC terminals. If the unit switches to high

speed, then the wires are not the problem. Replace the

push--button.

S

Ensure that the color--coded wires have been connected to

their appropriate places.

5. The defrost cycle

does not work

(the fresh air

duct is frozen

OR the fresh air

distributed is

very cold.)

S

Ice deposits may be hindering the

damper operation.

S

Remove the ice.

S

The damper rod or the port damper

itself may be broken.

S

Inspect these parts and replace if necessary.

S

The damper actuator may be

defective.

S

Plug in the unit and select “OFF”. Press the door switch and see if the

port damper closes. If it does not close, feed 120V directly to the damper

actuator. If the port damper still does not close, replace the damper

actuator.

S

The circuit board may be

defective.

S

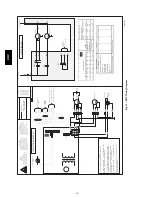

Unplug the unit. Unplug the defrost sensor wire (see J4 on electrical

diagram). Plug the unit back in. Select “MIN” and make sure the unit is

adjusted for low speed operation. Wait 3 minutes. The unit should switch

to high speed and the damper at the fresh air intake port should close

(defrost mode). If this does not happen, then replace the circuit board.

S

The thermistor may be defective.

S

If the defrost mode works well after having disconnected the thermistor

wire (above test), this means the thermistor is probably defective. It

should be replaced.

ER

V