16

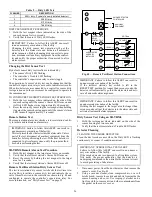

Compressor Rotation

NOTE: When the compressor is rotating in the wrong direction,

the unit makes an elevated level of noise and does not provide

cooling.

On 3-phase units with scroll compressors, it is important to be

certain compressor is rotating in the proper direction. To deter

-

mine whether or not compressor is rotating in the proper

direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge pres

-

sure should rise, as is normal on any start-up.

NOTE: If the suction pressure does not drop and the discharge

pressure does not rise to normal levels, the evaporator fan is prob

-

ably also rotating in the wrong direction.

4. Turn off power to the unit.

5. Reverse any two of the three unit power leads.

6. Reapply electrical power to the compressor. The suction

pressure should drop and the discharge pressure should

rise which is normal for scroll compressors on start-up.

7. Replace compressor if suction/discharge pressures are not

within specifications for the specific compressor.

The suction and discharge pressure levels should now move to

their normal start-up levels.

Filter Drier

Replace whenever refrigerant system is exposed to atmo

-

sphere. Only use factory specified liquid-line filter driers with

working pressures no less than 650 psig (4482 kPa).

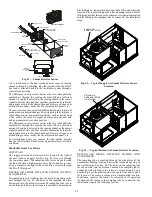

Condenser-Fan Adjustment

1. Shut off unit power supply. Install lockout tag.

2. Remove condenser-fan assembly (grille, motor, and fan).

See Fig. 26.

3. Loosen fan hub setscrews.

4. Adjust fan height by pushing fan until it stops on the fan

shaft.

5. Tighten set screw to 60 in.-lb (6.78 Nm).

6. Replace condenser-fan assembly. When replacing the

condenser-fan assembly follow the screw pattern sequence

shown in Fig. 27. The screws must be replaced in the

sequence shown in the figure.

Fig. 26 — Condenser Fan Adjustment

Fig. 27 — Condenser-Fan Assembly — Screw Pattern Sequence

CAUTION

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution can result in premature wear

and damage to equipment.

Scroll compressors can only compress refrigerant if

rotating in the right direction. Reverse rotation for

extended times can result in internal damage to the

compressor. Scroll compressors are sealed units and

cannot be repaired on site location.

CAUTION

EQUIPMENT DAMAGE

Failure to follow this caution can result in equipment

damage.

Do not install a suction-line filter drier in liquid line. A

liquid-line filter drier designed for use with R-410A

refrigerant is required on every unit.

1

2

3

4

5

NO SCREW

(Blank Tab)