6

FILTERING OUT

TROUBLE

A dirty filter will cause excessive stress

on the furnace blower motor and can

cause it to overheat and automatically

shut down. The furnace filter should be

checked every 4 weeks or so and

cleaned or replaced if necessary.

If installed with factory specified dis-

posable media filter, check or replace

filter before each heating and cooling

season. Replace disposable media filter

at least twice a year.

If your furnace filter needs replacing, be

sure to use the same size and type of fil-

ter that was originally specified.

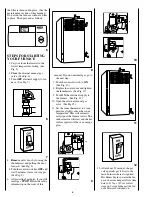

The air filter may be located in the filter

cabinet attached to the side or bottom

of the furnace.

If air filter has been installed in another

location, contact your dealer for instruc-

tions. To inspect, clean, and/or replace

the air filter(s), follow these steps:

1. Turn off electrical supply to fur-

nace (See Fig. 7.)

2. Remove filter cabinet door (See

Fig. 18 and 19.)

NOTE:

It may be necessary to re-

move 1 thumbscrew

3. Slide air filter out of filter cabinet.

Keep dirty side up (if dirty) to avoid

spilling dirt. (See Fig. 20 and 21.)

4. Inspect the filter. If torn, replace it.

NOTE:

If a washable filter has been re-

placed by:

a) Factory specified disposable media

filter – Do not clean. If dirty, replace only

with media filter having the same part

number and size. Install with airflow di-

rection arrow pointing towards blower.

b) Electronic air cleaner (EAC) – Re-

fer to EAC Owner’s Manual for mainte-

nance information.

5. Wash filter (if dirty) in sink, bath-

tub, or outside with a garden hose.

Always use cold tap water. A mild

liquid detergent may be used if nec-

essary. Spray water through filter in

the opposite direction of airflow.

CAUTION

Never operate your furnace

without a filter in place. Doing

so may damage the furnace

blower motor. An accumula-

tion of dust and lint on internal

parts of your furnace can

cause a loss of efficiency.

!

Allow filter to dry.

6. Reinstall clean air filter.

7. Replace filter cabinet door. (See

Fig. 22 and 23.)

8. Turn on electrical supply to furnace

(See Fig. 12.)

* Recommended ** Some furnaces may have 2 filters

Filters may be field modified by cutting filter material

and support rods (3) in filters. Alternate sizes and addi-

tional filters may be ordered from your dealer.

COMBUSTION AREA

AND VENT SYSTEM

Inspect the combustion area and vent

system before each heating season. An

accumulation of dirt, soot, or rust can

mean a loss of efficiency and improper

performance. Buildups on the main

burners can cause faulty firing. This

“delayed ignition’’ is characterized by

an alarmingly loud sound. If your fur-

nace makes a loud noise when the main

burners are ignited, shut down the fur-

nace—call your servicing dealer.

Use your flashlight and follow these

steps for inspecting the combustion

area and vent system of your furnace:

1. Turn off the electrical supply to the

furnace and remove the access

door. (See Fig. 7 and 8.)

2. Carefully inspect the gas burner

(See Fig. 17) for dirt, rust, or scale.

Then inspect the elbow, flue con-

nection area, and the vent pipe for

rust.

17

NOTE:

If dirt, rust, soot, or scale accu-

mulations are found, call your servic-

ing dealer. DO NOT OPERATE THE

FURNACE.

3. Inspect the vent pipe for a sag,

holes, or a disconnection. A hori-

zontal vent pipe must slope upward

away from furnace. If rusty joints

or seams, or signs of water leakages

are found, call your dealer for

service.

4. Restore electrical power to the fur-

nace. (See Fig. 12.)

5. Start the furnace and observe its

operation. If possible, watch the

burner flames. Are they burning

bright blue? If not (or if you suspect

some other malfunction), call your

servicing dealer.

6. Replace access door. (See Fig. 11.)

18

FURNACE

CASING

WIDTH

FILTER QUANTITY

AND SIZE

**

FILTER

TYPE

*

SIDE

RETURN

BOTTOM

RETURN

14-1/2

(1) 16 x 25

(1) 14 x 25

1” thick,

cleanable or

4-5/16” thick

media-type

17-1/2

(1) 16 x 25

(1) 16 x 25

1” thick,

cleanable or

4-5/16” thick

media-type

21

(1) 16 x 25

(1) 20 x 25

1” thick,

cleanable or

4-5/16” thick

media-type

24

(1) 16 x 25

(1) 24 x 25

1” thick,

cleanable or

4-5/16” thick

media-type

CAUTION

Use care when cutting support

rods in filters to protect

against flying pieces and

sharp rod ends. Wear safety

glasses, gloves, and appropri-

ate protective clothing. Failure

to follow this caution could re-

sult in personal injury.

!

WARNING

If holes are found—or if the

vent pipe is obstructed or is

not connected—toxic fumes

can escape into your home. DO

NOT OPERATE YOUR FUR-

NACE. Call your dealer for ser-

vice. A failure to follow this

warning could result in per-

sonal injury or death.

!