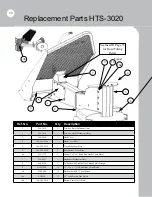

Replacement Parts HTS-3020

31

Ref. No.

Part No.

Qty Description

11

255-2601

10

Carbide Overlay Tooth, Flat Bottom

12

HS86S5C24

10

Hex Socket Shoulder ⅜” x 1 1/2” NC Grade 8

13

NNF85CZ

10

Nylock Flange Nut 5/16” NC Grade 8

14

260-3000

1

Bearing Block

Block Bolts

HC88C24Z

4

½-13x1.5” Gr. 8 bolts w/ ½” Grade 8 SAE Flat Washer WSA50Z8

15

233-260-3020B

1

Hydraulic Gear Motor 20 GPM B Frame

Motor Bolts

HC88C24Z

2

½-13x1.5” Gr. 8 bolts w/ ½” Grade 8 SAE Flat Washer WSA50Z8

16

260-2061

1

Locking Ring Plate 1.65 Hex Bore

17

260-2051

1

Locking Ring Plate Smooth Bore

17a

HC58C40Z

4

½”-13 x 2½” Bolt Grade 5 (Locking Ring Retaining Bolts)

17b

NNE50Z

4

½”-13 Nylon Lock Nut Grade 5 Zinc

18

260-1210

1

Herbicide Pump 1.0 GPM (See page 37 for Mounting Bolts)

19

233-260-2500

1

Hydraulic Control Block 20 GPM

19a

HS88S6C8

2

Hex Socket Bolt Grade 8 Shoulder ½”x½”x⅜” (Control Block Mounting)

19b

260-0051

2

Flanged Sleeve Bearing

20

235-6210

2

Sealed Bearing

21

260-2031

1

Rotation Drive Shaft

22

700-260-3530

1

Thrust Spacer

13

12

14

21

17

19

20

18

22

15

16

11

260-0550

Saw Blade Detail

Hydraulic Motor Lines on

Page 36-37

Summary of Contents for HTS-3020 3000

Page 24: ...Maintenance 24 ...

Page 27: ...27 Notes ...