KNOWING YOUR SEWING MACHINE

20

REPLACING THE NEEDLE

This section provides information on sewing machine

needles.

Needle precautions

Be sure to observe the following precautions

concerning the handling of the needle. Failure to

observe these precautions is extremely dangerous.

CAUTION

• Only use home sewing machine needles. Use

of any other needle may bend the needle or

damage the machine.

• Never use bent needles. Bent needles can

easily break, possibly resulting in injury.

Needle types and their uses

The sewing machine needle that should be used

depends on the fabric and thread thickness.

Fabric Type/

Application

Thread

Size of

Needle

Type

Size

Medium

weight

fabrics

Broadcloth Cotton

thread

60–90

75/11–90/14

Taffeta

Synthetic

thread

Flannel,

Gabardine Silk thread 50

Thin

fabrics

Lawn

Cotton

thread

60–90

65/9–75/11

Georgette

Synthetic

thread

Challis, Satin Silk thread 50

Thick

fabrics

Denim

Cotton

thread

30

100/16

50

90/14–100/16

Corduroy

Synthetic

thread

50–60

Tweed

Silk thread

Stretch

fabrics

Jersey

Thread for

knits

50–60

Ball point needle

75/11–90/14

(gold colored)

Tricot

Easily frayed fabrics

Cotton

thread

50–90

65/9–90/14

Synthetic

thread

Silk thread 50

For top-stitching

Synthetic

thread

Silk thread

30

100/16

50–60 75/11–90/14

Note

• Never use a thread of weight 20 or lower. It may

cause malfunctions.

Memo

• The lower the thread number, the thicker the

thread; and the higher the needle number, the

thicker the needle.

■

Ball point needle

Use the ball point needle when sewing on stretch

fabrics or fabrics where skipped stitches easily

occur.

Use the ball point needle for best results when

sewing patterns using monogramming foot “N”.

■

Transparent nylon thread

Use a 90/14 to 100/16 needle, regardless of the

fabric or thread.

CAUTION

• The appropriate fabric, thread and needle

combinations are shown in the table. If the

combination of the fabric, thread and needle

is not correct, particularly when sewing thick

fabrics (such as denim) with thin needles (such

as 65/9 to 75/11), the needle may bend or

break. In addition, the stitching may be uneven

or puckered or there may be skipped stitches.

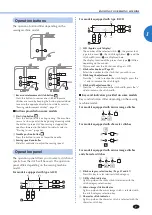

Checking the needle

Sewing with a bent needle is extremely dangerous

since the needle may break while the machine is

being operated.

Before using the needle, place the flat side of the

needle on a flat surface and check that the distance

between the needle and the flat surface is even.

1

2

1

Flat side

2

Needle type

marking

3

4

3

Flat surface

4

Even

3

5

5

Not even