24

•

BREAKDOWN OF THE FUEL LOADING MOTOR

If the geared motor stops, the stove keeps on working (only the smoke extractor) until the minimum working smoke temperature goes down

and stops.

•

TEMPORAL POWER LOSS

After a short lack of electricity, the equipment will restart automatically. In the event of a lack of electricity the stove may give off a small

amount of smoke inside the room for a period of time of 3-5 minutes.

THIS DOES NOT ENTAIL ANY HEALTH RISK

. This is

a reason why Bronpi advises, whenever possible, to connect the primary air inlet pipe to the exterior of the house in order to

assure that the stove does not give off smokes after a short power loss.

•

ELECTRICAL PROTECTION

The stove is protected against abrupt electricity oscillations through a general fuse placed in the back part. (4A250V

Retarded) (

see drawing D1

).

•

SMOKE OUTLET PROTECTION

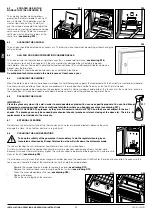

The electronic pressure switch blocks the operation of the stove in the event of an abrupt change of the pressure inside the

combustion chamber (door opening, breakdown of the smoke extraction motor, smoke returns etc). If this happens, the machine will go into

an alarm state (

see drawing D2

).

•

PROTECTION IN THE EVENT OF HIGH TEMPERATURE OF PELLET (80ºC)

In the event of overheating of the internal part of the tank, this device stops the operation of the machine. The restart

needs to be done manually by an authorised technician (

see drawing D3

).

The replacement of the 80ºC safety device is not included in the warranty unless the technical assistance

centre can demonstrate a faulty component.

•

WATER OVERHEATING PROTECTION (90ºC)

If the water temperature inside the circuit reaches near about 100ºC,

the fuel loading is blocked. If the temperature is activated, the restart

needs to be done manually by an authorised technician (

see drawing

D4

).

The replacement of the 90ºC safety device is not included in the

warranty unless the technical assistance centre demonstrates a

faulty component.

•

FLOW SENSOR (OASYS TECHNOLOGY).

Your stove has a flow sensor (

see drawing D5

) placed inside the inlet of the primary air pipe that detects the

proper circulation of combustion air and the smoke exhaust. In case of insufficient air inlet (due to incorrect smoke

outlet or improper air intake), the sensor sends a “block” signal to the thermo-stove.

The OASYS TECHNOLOGY (Optimum Air System) ensures a constant combustion by controlling automatically

the draught according to the characteristics of the flue (curves, length, diameter, etc) and the environmental

conditions (wind, humidity, atmospheric pressure, etc). To that end, the fitter must access the technical menu the

geographical altitude of the equipment installation place.

•

HYDRAULIC PRESSURE TRANSDUCER

If the pressure of the heating system is lower than 0.4 bars, the boiler will cease feeding fuel and

ultimately close down and stop.. If the pressure inside the heating system exceeds 2.5 bars, the display

will show the alarm “WATER PRESSURE FAILURE”. To reset the safety device press button no. 4 (On/Off)

on the display for, at least, 3 or 4 seconds (

see drawing D6

).

Warning: the presence of air in the installation can provoke the intervention of the pressure

transducer.

If the device intervenes blocking the fuel load in the machine, the alarms related to the lack of fuel may activates.

In order to get a proper performance of the product, the ideal pressure of the installation should be set in, approximately, 1.0-1.4 bars when

the installation is cold. Furthermore, it is necessary the absolute absence of air.

Bronpi Calefacción advises to have an adequate air

purged circuit inside the installation. The occasional operation of air purging inside the installation or the product is not included in

the warranty.

•

INSTALLATION SAFETY DEVICES

It is COMPULSORY to have a pressure gauge to visualize the water pressure of the heating circuit.

WARNING!!

The closed expansion tank of the installation should have a dimension between 4 and 6% of the total volume of installation. This is

why the standard closed expansion tank is likely to be inadequate in case of high water volumes.

5

INSTALLATION POLICY

The way of installing the thermo-stove will affect the safety and the proper operation. For this reason, it is essential that the installation is

carried out by qualified installers and informed about the compliance with the installation and safety norms.

If your equipment is not properly installed, it may cause serious damage.

Before the installation, carry out the next series of checks:

•

Make sure that the floor can sustain the weight of the equipment and make a proper isolation in the case that it is made of flammable

material (wood) or a material that can be affected by a thermal shock (plaster, for example).

•

If the equipment is installed on a floor which is not completely refractory or inflammable such as parquet, carpet, etc, it is necessary to

replace this part or introduce a fire-resistant base so that it protrudes out the oven 30 cm. Example of materials include steel flooring,

glass base or any other type of fire-resistant material.

•

Make sure that there is proper ventilation in the place where it is installed (air intake).

D3

D2

D5

D4

D6

D1

FUSE

INSTALLATION, OPERATING AND SERVICING INSTRUCTIONS

HYDRO SERIES

EN

Summary of Contents for Dama Hydro

Page 107: ...106 12 1 DAMA H FT ...

Page 109: ...108 12 2 LETICIA H FT ...

Page 111: ...110 12 3 REYNA H FT ...