Cartridge Maintenance

We advise that the TMV is regularly

serviced in hard water areas to

maintain the flow of water.

Isolate both hot and cold water

supplies to the mixer tap

Pull both shrouds away from the wall

surface to expose the filters. Isolate

both water supplies to the mixer by

unscrewing the filters fully, using a

10mm hexagonal key until there is

resistance. Stop using the key at this

point and use fingers to “wiggle” the

filter out.

NOTE:

Turning the hexagonal key

too far may result in seizing of the

filters.

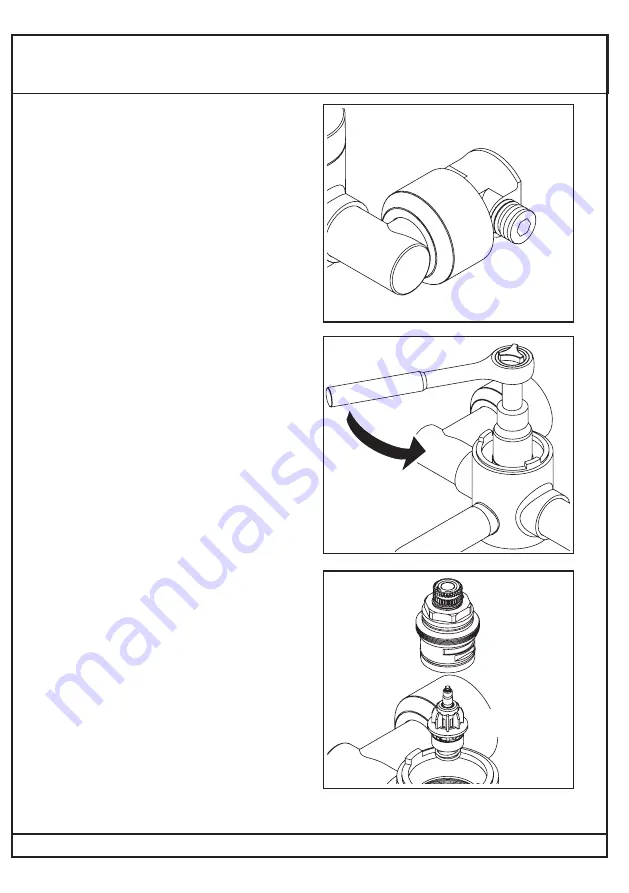

1. Remove the control handle lever.

remove the cap and undo the screw

and remove the lever.

2. Unscrew the cartridge nut anti-

clockwise using a 30mm socket and

remove the cartridge from the TMV

body.

3. Place the cartridge in a suitable

solution until the cartridge is fully

de-scaled. Rinse thoroughly with

clean water to remove any debris.

4. Grease the seals with a

WRAS approved silicon grease

and carefully refit the cartridge.

5. Replace the lever handle, tighten

the grub screw and push-fit the cap

into position.

Shroud

Cartridge

Piston &

Thermostat

Filter

Need help?

Give us a call on

0330 026 6273

and speak to one of our trained advisors.

Maintenance

14