www.bresser.de

62

④

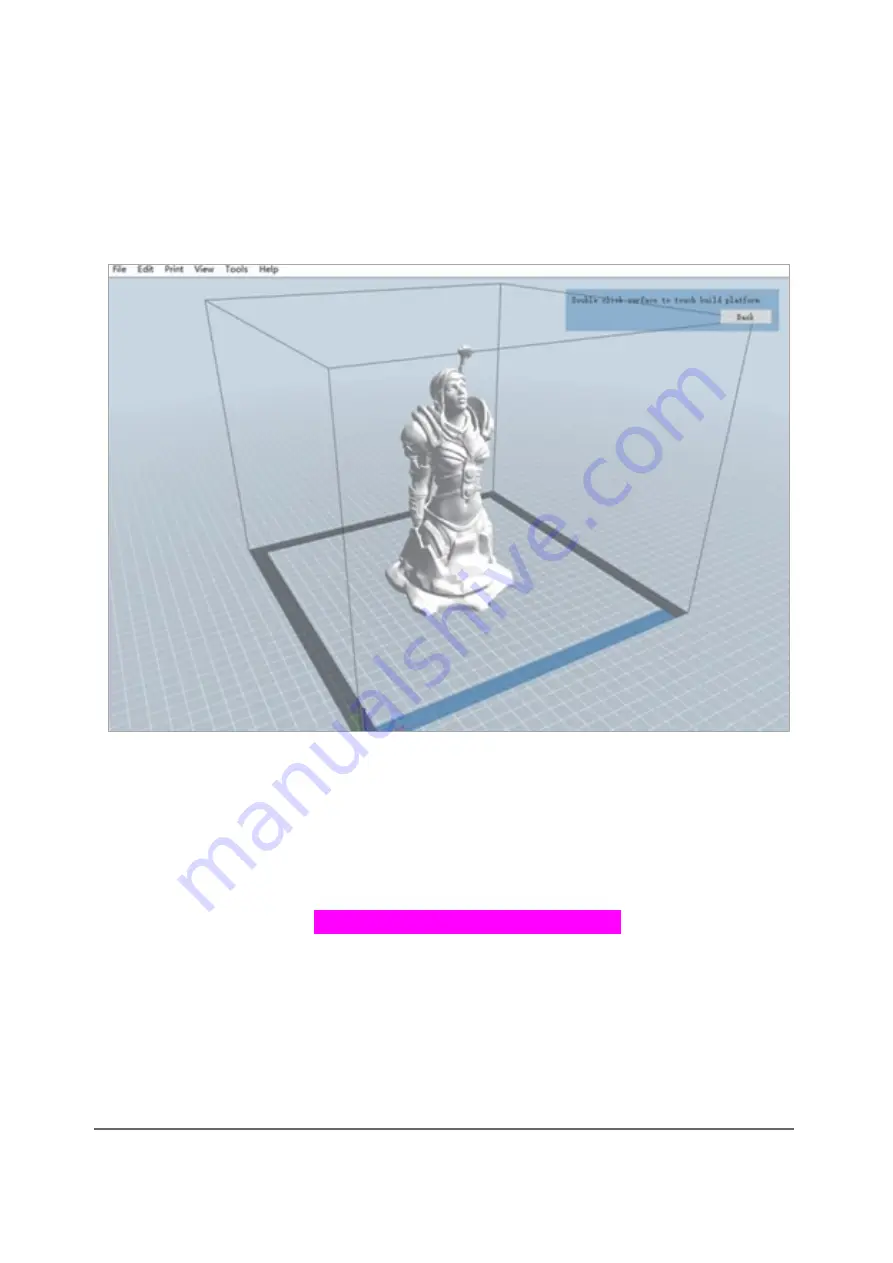

Click the Load icon to load a .STL model file. The model will display within the

build area.

⑤

Double-click the Move icon, then click the On the Platform and Center

buttons to ensure the model is in contact with the centre of the build

platform

⑥

Click the

icon, then change the settings as appropriate for your

filament type and model.

Preview

: Check the

Preview

box if you want to preview the model after

slicing is done.

Print When Slice Done

: Because we are printing from the SD™ card, uncheck

this box to save the Gcode file to the SD card.

Machine Type

: Select

Flashforge Creator Max 3D Printer

.

Material Right

: Select the type of filament you are using.

Material Left

: Select the type of filament you are using.

Supports

: If your model has overhanging elements, enable the

Supports

option.

Raft

: It is recommended to enable the

Raft

option.

Resolution

: It is recommended to select the

Standard

option.

More Options

: It is recommended to leave them at the default values.

Summary of Contents for 2010500

Page 1: ...WIFI 3D Printer Twin Extruder Art No 2010500 Instruction Manual...

Page 8: ...www bresser de 8...

Page 40: ...www bresser de 40 The following screenshots illustrate the five basic shapes Plane Tube...

Page 41: ...www bresser de 41 Canister Lamp...

Page 42: ...www bresser de 42 Seal...

Page 66: ...www bresser de 66...

Page 67: ...www bresser de 67...