8

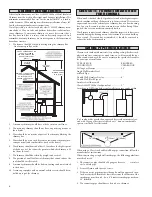

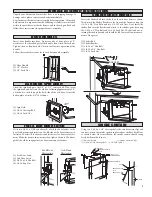

INSTALLATION #3

The baffle on this system should be made the full width of the furnace

plenum in order to properly direct the air into the distribution ducts.

INSTALLATION #2

Extending the hot air duct from the furnace into the existing plenum

will help direct the flow of air from the furnace as well as the flow in

the existing furnace. Ducting entering the existing plenum at an angle

(approximately 45 degrees) will facilitate air flow from the furnace while

diverting air from the existing furnace.

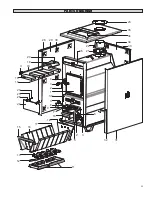

THE PLENUM OPENINGS DIFFER

BETWEEN THE 1602 AND 1802

MODEL 1602 -

13” x 18” Rectangular

MODEL 1802 -

18” x 18” Rectangular

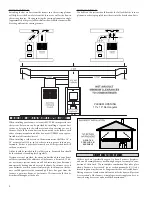

RETURN AIR IS VERY IMPORTANT

When installing your furnace, return air MUST BE incorporated into

the system. Return air can be provided by installing a separate duct

system or by tying into the cold air return of an existing gas or oil

furnace. The cold air return duct can be connected to the furnace with

either a factory manufactured filter box, model UFB908 or an equiva

-

lent fabricated from sheet metal.

When installing a cold air return, the minimum size shall be a 16” x

20” or equivalent (320 sq. in.) in order to insure proper furnace per

-

formance. Failure to provide return air ducts of the specified size will

void your warranty.

A filter should be installed in the cold air return. Furnace filters should

be checked and cleaned/replaced regularly.

If return air is not provided, the warm air distributed into your home

will be restricted and the efficiency of the furnace is decreased. With

-

out a return air system, warm air will be drawn into your basement,

unnecessarily heating unused areas of the home. In extreme cases, if

your basement or utility room is fairly airtight, the blowers on the fur

-

nace could depressurize the room and pull toxic flue gases from the

furnace, a gas water heater, or gas furnace. The fumes could then be

distributed throughout the house.

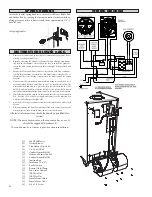

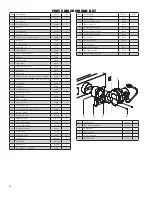

COMBUSTION AIR

All fires need air (specifically oxygen) to burn. Furnaces, fireplaces,

and wood burning furnaces need enough oxygen for complete com

-

bustion of their fuels. The incomplete combustion that takes place

when a furnace is “air starved” causes carbon monoxide (CO) to be

formed in quantities that can be dangerous inside a well sealed house.

Having a source of combustion air from outside the home will prevent

“air starvation” of the furnace. A simple positive air supply can be con

-

structed using dryer vent and a modified termination.

NEGATIVE

PRESSURE IN

BASEMENT

PLENUM OPENING

13” x 18” Rectangular

Summary of Contents for SF747

Page 2: ...2...