Tri Lok

®

Cryogenic Valve

Installation, Operation and Maintenance Manual

TRI LOK

®

CRYOGENIC TRIPLE OFFSET VALVE

| 2

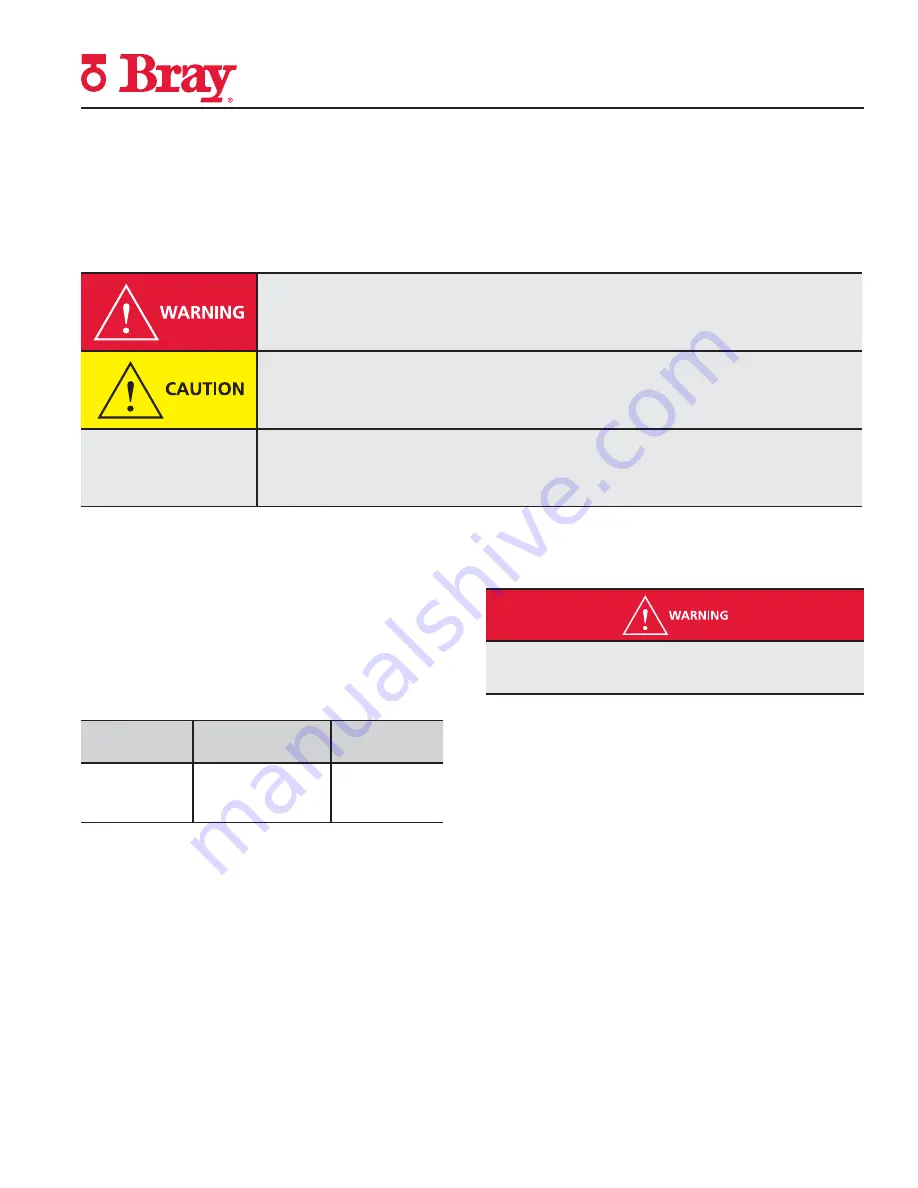

DEFINITION OF TERMS

indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury

indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury

NOTICE

used without the safety alert symbol indicates a potential situation which, if not avoided, may

result in an undesirable result or state, including property damage

Read and Follow These Instructions

Save These Instructions

1.0 INTRODUCTION

Information provided in this manual is for cryogenic

Tri Lok configuration only. Specific instructions for

non-standard materials of construction, temperature

range, etc. should be referred to the factory.

This manual covers Tri Lok valves in the following range:

ASME

Class

Size

Body Style

150, 300,

and 600

3” - 48”

(80mm - 1200mm)

Wafer

Lug

Double Flange

The Tri Lok metal seated valve is fully rated to ASME

B16 34, and complies with API 609

Tri Lok is torque-seated Torque must be continually applied

by an actuation device (manual gearbox or power valve

actuator) to the valve stem to ensure the valve seals against

the line pressure

Do not remove or de-energize actuation devices while the valve

is under line pressure

The valve is inherently fire safe, and has been qualified to

ISO 10497 and API 607 standards

The preferred direction of valve installation is with the

upstream line pressure on the stem side and the body seat

on the downstream side

The preferred direction of flow is indicated by an arrow on

the valve nameplate