A.1 -

Visually inspect the parts provided by Bravo Systems for In-transit damage and/or missing

parts. Continue to keep the Sump clean of debris throughout your installation process.

A.2 -

Set your B409 Piping Sump where it must be per site plans. Secure the Sump to avoid

movement while penetrating.

A.3 -

Mark where you will penetrate the Base/Tank Collar wall.

A.4 -

Install Penetration Fittings per their respective Installation Instructions. You must NOT

disturb the penetration fittings while the sealant/adhesive is drying. Allow for the maximum cure time

as recommended by the manufacturer of the fittings before pressurizing & soaping to test for leaks.

DO NOT FILL DOUBLE WALL PENETRATION FITTINGS

WITH FOREIGN MATERIALS, SEALANTS or ADHESIVES.

5

ii-B409-DW-10A

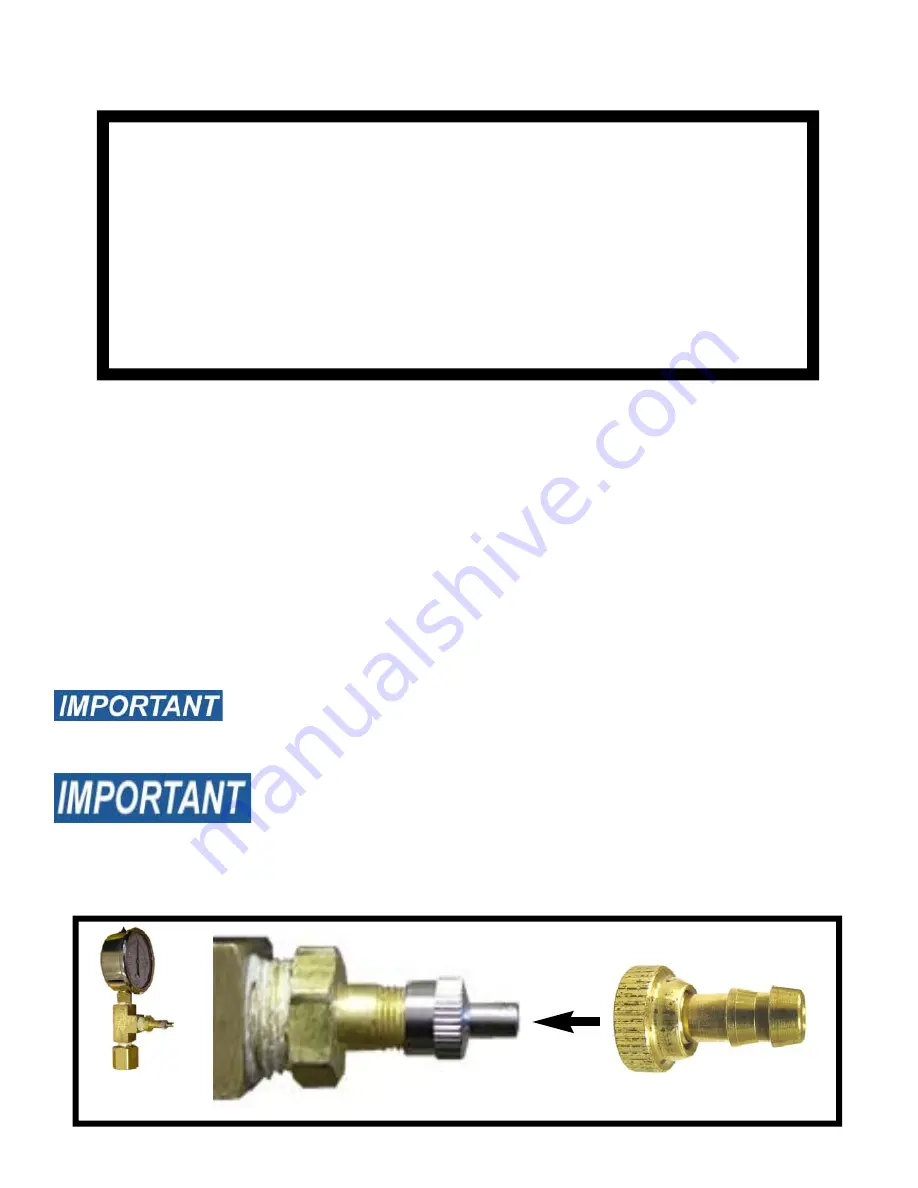

Gauge

Assembly

SVA-BARB

CAP

While Fiberglassing, curing, or sitting overnight, keep the

SVA-BARB in place. This will relieve pressure on the Interstice

while the sumps are heating up or cooling off.

SAVE THESE PIECES, DO NOT LOSE THEM!

Remove the SVA-BARB when ready to test.

A -

INSTALLING AND SECURING YOUR B409

BEFORE INSTALLING PENETRATION FITTINGS

ENSURE THAT THE SUMP BODY IS HOLDING VACUUM.

If the gauge is Below 12 inches of mercury (Hg/Vacuum), then pressurize the

sump interstice to 4 PSI and submerge the gauge and tubing assemblies.

Soap test the test tubing fittings on the walls. If an air leak is found, contact

the factory. If no leak at the tubing

is found, soap test the rest of the sump

surface starting with the exterior. Visually inspect for damage. If the leak is found,

patch per repair directions in this manual.

If the gauge is

AT OR ABOVE 12 INCHES OF MERCURY

, proceed to

Step A.1