Page 17

Page 16

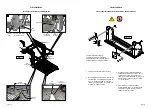

Lift Installation

Platform Angle Adjustment

Lift Installation

Turnbuckle Installation and Adjustment

36514

Hinged platform halves are secured with and

rotated on turnbuckles. Platform turnbuckles are

fully adjusted during assembly procedures (control

platform alignment and leveling). Turnbuckles

are disconnected from the platform brackets for

shipping purposes. Vibration during shipment can

potentially affect turnbuckle adjustment.

1. Using the hand pump, carefully deploy platform

to floor level. Be sure the platform stop blocks

are in contact with the vertical arms (Photo A).

Warning: Keep clear of platform area during

hand pump deployment. Hinged platform

halves are not secured and could free fall.

2. Manually unfold both platform halves. Keep

Hands Clear! The left platform tab must

engage the right platform slot. See Photo D.

3. Both platform halves must be laying flat as

shown in Figure 2. Install the left turnbuckle

into the platform bracket with the turnbuckle

stud facing outward (Photo B, right side

shown). Adjust turnbuckle so stud enters

the platform bracket and no tension is on the

turnbuckle (adjust if needed only). No further

adjustment of the left turnbuckle is necessary.

4. Install right turnbuckle into the platform

bracket with the turnbuckle stud facing

outward (Photo B).

5. Adjust right platform turnbuckle so that the

inboard end of the right platform is slightly

above the platform heel (Photo C).

6. Stow and deploy platform. Observe the

platform tabs and platform slots to confirm

proper alignment during platform deployment.

If the left platform tabs are higher than the right

platform slots, increase the length of the right

turnbuckle (Figure 1). If the tabs are lower

than the slots, decrease the length of the right

turnbuckle.

Note:

Loosen jam nut

to adjust turnbuckle

length. Tighten jam nut

after adjustment.

Shorten

Turnbuckle

Lengthen

Turnbuckle

Jam Nut

Figure 1

Figure B

Lowering Sequence Requirements

1. The outboard end (toe) of

the platform must contact

the ground first to ensure the

spring-loaded outer barrier

unfolds fully. See Figure B.

2. The inboard end (heel) of the

platform must lower fully (turn-

buckle brackets must contact

ground when fully lowered).

See Figure B.

The angle of the platform at

ground level directly affects the

angle of the platform when posi-

tioned at floor level.

Raise the platform to floor level.

Note the angle of the platform.

The platform at floor level should

have a slight upward angle as

shown in Figure C.

Adjust platform angle as detailed

below.

Floor

Level

Wedges (option)

Figure C

(Heel) Inboard

Outboard (Toe)

Rear

Front

Outboard

(passenger's side)

Inboard

(driver's side)

“Arrows/Direction

(of vehicle)

(of vehicle)

Heel

Ground Level

Barrier must

unfold

fully.

Platform heel

must lower

fully.

Barrier

2

1

Adjustment Procedure:

Platform angle adjustment

Allen screws are provided on

each side of the platform (see

photo at right).

Turn adjustment screws clock-

wise to raise the outboard end

of the platform. Turn adjust-

ment screws counterclockwise

to lower the outboard end

of

the platform.

Both adjustment screws must

be adjusted equally.

Platform Stop Blocks:

When

adjusting platform angle, en-

sure both stop blocks are mak-

ing full contact with the vertical

arms (see photo at right).

Floor Level Adjustment:

Following platform angle

adjustment, set platform

floor level positioning as

detailed in Tower Micro-

switch Adjustmen

t.

Check

platform angle again

after performing Tower

Microswitch Adjustment

procedures.

Turnbuckles:

Platform

turnbuckles will be affected

if platform angle is ad-

justed. Adjust turnbuckles

as detailed in Turnbuckle

Adjustment section if

needed.

Stop

Block

Vertical

Arm

Adjustment Screw

Stop blocks must

make full contact.

A

36514