2.9 Connecting the Printer to the mains and computer

The mains is connected trough the Paper Roll Feeder for all the units.

Note! If the plug on the mains power cable is to be replaced with one that is compatible with the local

electric contact points, observe that the yellow/green wire is the grounding (earthing) wire. Also make

sure that you are connecting to

230 V 50/60 Hz!

ALWAYS CONNECT THE YELLOW/GREEN WIRE IN THE MAINS CABLE TO

GROUND!

Connecting to the computer

This can be done either with USB or with Ethernet.

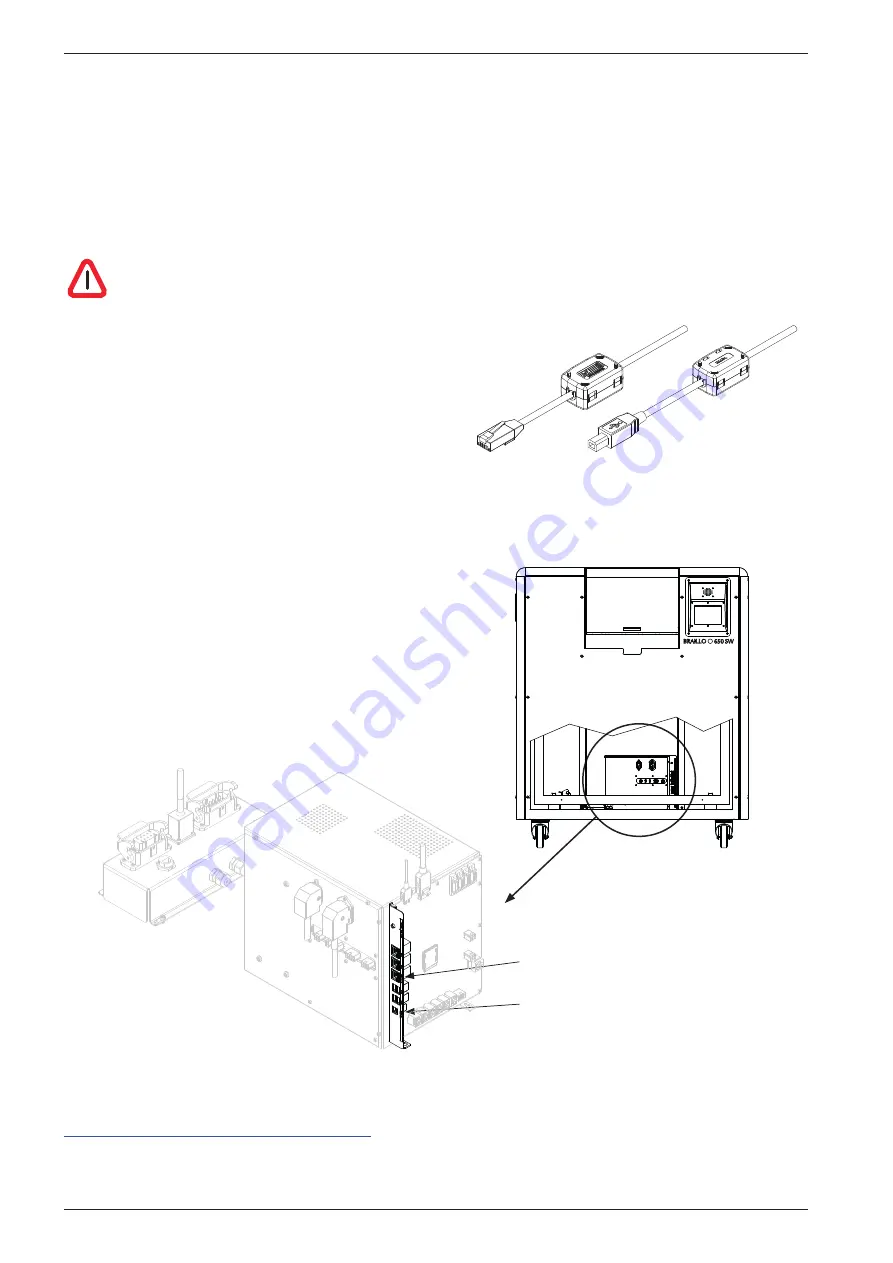

When connecting the USB or the ethernet cable,

make sure the end with the ferrite bead is connected

to the printer.

There is no need to select which of the two input to use. The Printer will connect to the input who

receives data first. Meaning, if data comes on the ethernet, the USB will not be operative before the

ethernet have finished the transmission. It is a rather large text buffer in the Printer, so the text

file will be transferred to the Printer as fast as the

transmission will allow. Then the Printer will run until

the text buffer is empty.

See figure below.

Ethernet

USB

For the latest instruction on how to install the printer on your computer, see the information here:

http://braillo.com/braillo-owner-resources/

BRAILLO

l

B 650 SW

24

Summary of Contents for 650 SW

Page 1: ...BRAILLO L NORWAY FOR BETTER BRAILLE AND MORE User s Guide BRAILLO 650 SW Rev January 2018 ...

Page 2: ... 2018 Braillo Norway AS ...

Page 4: ...BRAILLO l B 650 SW 4 ...

Page 96: ...Frame complete BRAILLO l B 650 SW 96 ...

Page 123: ...BRAILLO l B 650 SW 123 115 cm 77 cm 112 cm 8 5 Measurements All measurements in centimetres ...

Page 124: ...9 GENERAL INFORMATION 9 1 Declaration of conformity BRAILLO l B 650 SW 124 ...