3

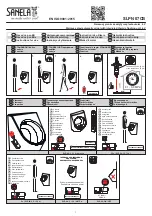

Installation

S19-120HFP

Bradley•

215-148HFP Rev. K; ECN 12-05-016E

8/9/2012

Installation

Supplies Required:

•

Teflon tape and pipe sealant

•

Miscellaneous piping (refer to

dotted lines)

•

Piping to 1" NPT water supply

inlet and 1/4" NPT female

weep connection

•

Adequate supply pipe supports

•

Minimum 4" drain to

accommodate 30 gallons per

minute discharge for shower

waste

•

OPTIONAL: sign-mounting

hardware

Step 1: Assemble

components

1. Assemble the components as

shown on page 4.

•

Apply pipe sealant to all

male-threaded pipe joints.

•

Use a strap wrench around

pipes when tightening to

prevent marring.

•

Bottom edge of

showerhead should be

7'-0" (2134 mm) from the

floor.

Step 2: Install operating

stem support sleeve

This unit has been designed to accommodate varying wall thicknesses. When installing the operating stem support sleeve it

will be necessary to cut off one or both ends of the sleeve so that 5/8” of threaded pipe protrudes from both sides of the wall.

1. Connect water supply piping to 1" NPT inlet on unit (piping supplied by installer). Provide adequate

supports (supplied by installer) for supply pipe using pipe hangers or other means.

2. Hang the safety sign from the unit with the curtain hooks provided (or mount it to the wall using sign-

mounting hardware by installer).

3. Open water supply lines. Test for leaks and adequate water flow.

Step 3: Connect water supply

Do not rely on Bradley’s Drench Shower to support supply piping.

1. Connect water supply piping to 1" NPT inlet on unit (piping supplied by installer). Provide adequate

supports (supplied by installer) for supply pipe using pipe hangers or other means.

2. Connect drain piping (supplied by installer) to the 1-1/4” NPT female weep connection.

3. Hang the safety sign from the unit with the curtain hooks provided (or mount it to the wall using sign-

mounting hardware by installer).

24"

(610mm)

All dimensions assume standard thread engagement.

Variations in manufacturing allow for +/- 1/8"

(3mm) per threaded joint. To find the tolerance of a

dimension, add the number of thread joints in between

a dimension and multiply it by 1/8" (3mm).

4" (102mm)

minimum will

increase with

change in wall

thickness

2-5/8"

(67mm)

7'-0"

(2134mm)

to Floor

Ø 3.1"

(78.7mm)

3-1/2"

(89mm)

4-1/2"

(114mm)

6-1/4"

(159mm)

1-3/4"

(44mm)

Ø 1"

(25mm) Hole

36"

(914mm)

to Floor

Ø 1-3/8" (35mm)

Hole

S19-120HFP8

(0"−8" wall)

S19-120HFP12

(8"−12" wall)

S19-120HFP18

(12"−18" wall)