Fault finding and diagrams

Greenstar Utility

ErP -

6 720 821 751 (2018/04)

42

8.2

Burner fault indicator diagnostics

When the lockout LED illuminates, the burner will attempt to restart only after pressing the reset button. After that, if the burner is working properly, the

trip can be attributed to a temporary fault that is not dangerous.

Otherwise, if the trip persists, the cause of the fault must be sought and the solutions indicated in Table must be implemented.

Key to symbols

8.3

Riello control box

8.3.1

Control box LED codes

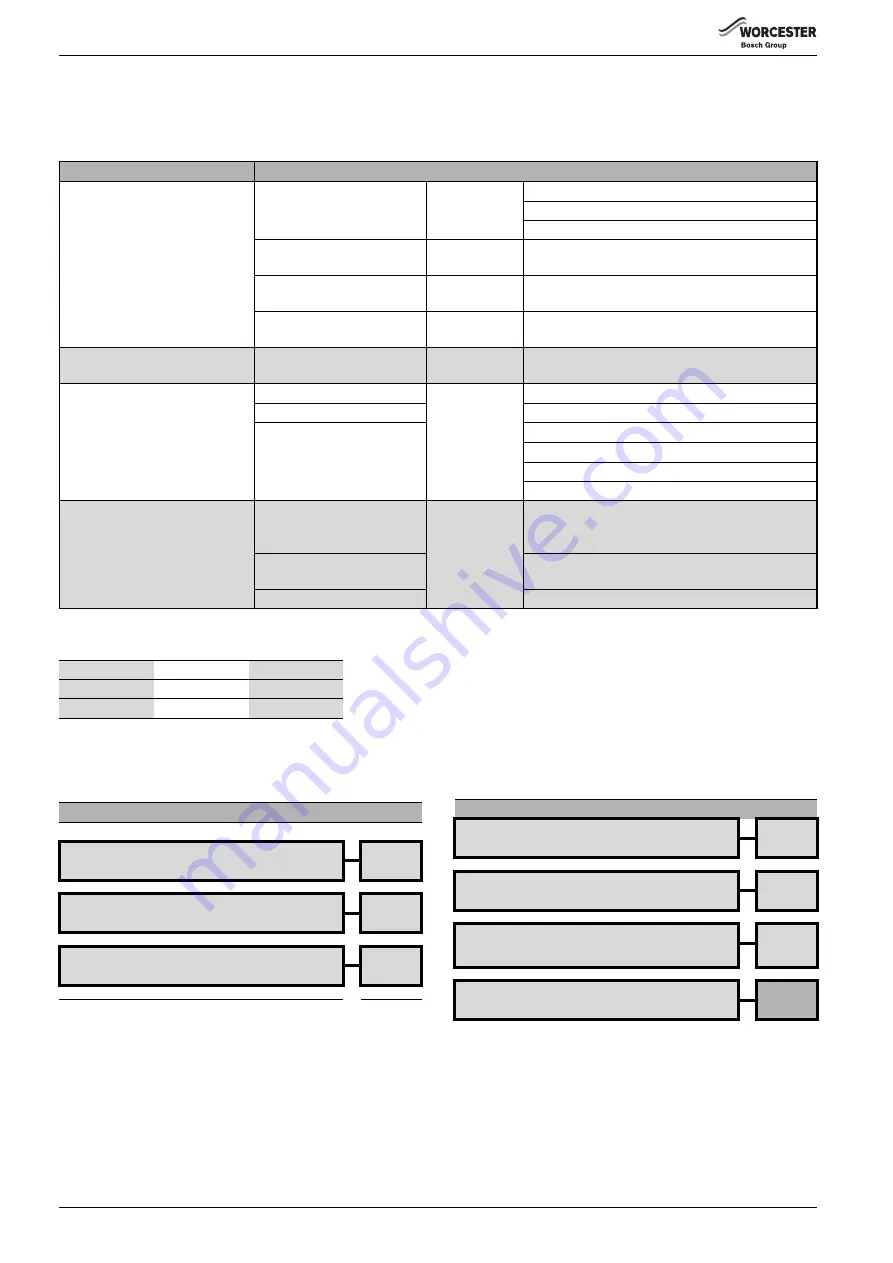

Problem

Possible cause

Fault indicator

Possible solution/check

The burner does not start

Lack of electrical supply,

OFF

▶ Check presence of voltage on the L - N pin plug

when there is heat demand.

▶ Check the conditions of the fuses

▶ Check the safety thermostats are not in lockout

The flame detector sees

extraneous light.

▶ Eliminate the extraneous light

The connections in the control

box are wrongly inserted.

OFF

▶ Check and correct all the plugs and sockets properly

The pre-heater link is missing or

incorrectly fitted.

▶ Check and connect link correctly/replace link

The burner goes into lockout mode

before or during the pre-purging.

The flame detector or sees

extraneous light.

▶ Check for and eliminate any extraneous light

Burner runs normally in the

The photocell is dirty.

Red

▶ Clean it

pre-purge and ignition cycle and

The photocell is faulty.

Steady ON

▶ Replace it

looks out after about 5 seconds.

Flame moves away or fails.

▶ Check pressure and output of the fuel

▶ Check air output

▶ Check oil nozzle

▶ Check the coil of solenoid valve

Burner starts with an ignition delay

The ignition electrodes are

damaged or incorrectly

positioned.

OFF

▶ Replace the blast tube and electrode assembly

Air output is too high.

▶ Set the air output according to the instructions of this

manual

Oil nozzle dirty or worn

▶ Replace it

Table 18 Burner fault indicator diagnostics

ON

OFF

Colour code

Red

Green

Table 19

Lockout types (burner in lockout)

Refer to Fault finding chart, section 8.3.2, go to line number on chart

RED steady ON

Lockout for no flame after safety time

[3]

RED 0.5 seconds ON/ RED 0.5 seconds OFF

Lock out for false flame signal

[5a]

RED 0.2 seconds ON /RED 0.2 seconds OFF

Lock out for maximum number of flame loss re-lights

[9]

Table 20

RED 2.5 seconds ON / ORANGE 0.5 seconds ON

Lock out for fan motor failure

[3d]

RED 2.5 seconds ON / GREEN 0.5 seconds ON

Lock out for oil valve circuit driver failure

[8c]

ORANGE 0.5 seconds ON / GREEN 0.5 seconds ON

Lock out for EEPROM failure

Replace

control

box

Red 0.5s ON / Red 2.5s OFF

Max pre-heat time exceeded (10 minutes)

[2]

Lockout types (burner in lockout)

Table 20