English - 4

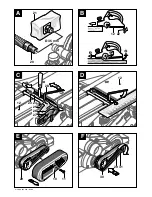

Using the Parallel/Beveling Guide

(Accessory)

Mount parallel guide 14 or beveling guide 18 to

the machine using fastening bolt 15 and rebating

depth stop 2 using fastening bolt 1.

Loosen locking nut 16 and adjust the required re-

bating width with the scale 17. Retighten locking

nut 16 again.

Adjust the required rebating depth accordingly

with the rebating depth stop 2.

Carry out the planing procedure several times,

until the required rebating depth is reached. Pay

attention that the planer is guided with sideward

supporting pressure.

Beveling (only beveling guide 18)

When beveling rebates and

surfaces, adjust the required

slope angle with the angle

adjustment 19.

■

Before any work on the machine itself, pull

the mains plug.

■

Be cautious when replacing the planer

blades: Possible danger of injury due to the

sharp cutting edges of the planer blades!

Do not grasp the planer blades by the cut-

ting edges.

■

Use only original Bosch carbide

blades (TC).

The carbide blade (TC) has 2 cutting edges and

can be reversed.

When both cutting edges are dull, the planer

blade must be replaced. The carbide blade (TC)

may not be resharpened.

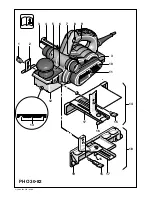

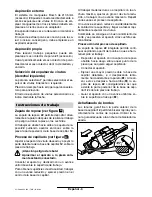

Storage Compartment for

Planer Blade/Allen Key

A planer blade 26 and an Allen key 28 can be

housed in the storage compartment 4 as shown

in the figure.

To remove the contents in the compartment,

completely pull the storage compartment for the

planer blade/Allen key 4 out of the planer.

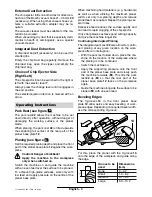

Disassembling the Planer Blade(s)

(see figure

)

To reverse or replace the planer blade, rotate the

blade drum 23 until it is parallel to the planer base

plate 12.

➊

Loosen the two fastening screws 25 with the

Allen key 28 by approx. 1 – 2 turns.

➋

If necessary, loosen the clamping element 24

by giving it a light blow with a suitable tool

(e. g. a wooden wedge).

➌

After pressing down the lateral blade-shaft pro-

tector 27, push the planer blade 26 sideward

out of the blade drum using a piece of wood.

Assembling the Planer Blade(s)

(see figure

)

The guide groove of the planer blade always en-

sures continuous height adjustment when replac-

ing or reversing it.

Clean the blade seat (clamping element) and the

planer blade respectively, if required.

When assembling the planer blade, ensure that it

is seated properly in the blade holder of the

clamping element 24 and aligned flush at the side

edge of the rear planer base plate 12.

Afterwards tighten the fastening screws 25

again.

■

Before restarting, check if the fastening

screws 25 are tightened well.

■

Rotate the blade drum 23 by hand and en-

sure that the planer blade does not run into

the planer base plate or housing.

Replacing the Planer Blade

26

28

C

D

12 • 2 609 932 233 • TMS • 12.05.03