-12-

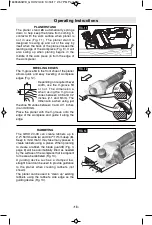

of scrap wood

31

(at least 1-1/2" [38 mm]

thick) on the end of the workpiece

30

,

aligned with the surface to be planed (Fig.

9). Doing this moves the location of a

potential divot off the workpiece and on to

the piece of scrap wood.

5. Feed the planer at a uniform and reasonable

rate that does not put excessive strain on

the motor or blade, (do not pull the planer

back over the surface already cut.)

6. Use progressive cuts until you are near the

desired depth, and then re-adjust to a thin

cut for the final pass to obtain a good

surface finish.

The motor may stall if

improperly used or

overloaded.

Reduce the pressure (feed rate)

or depth of cut to prevent possible damage to

the tool if the motor labors.

DEPTH OF CUT AND FEED RATE

The cutting depth (planing depth) is

determined by the difference in height between

the adjustable front shoe

13

and the fixed rear

shoe

9

of the planer. The depth knob

1

adjusts

the front shoe

13

, which retracts and exposes

the blade and determines the amount of

material removed from the workpiece.

The appropriate depth of cut and feed rate

depends on the workpiece material:

To avoid clogging and/or damage to the motor,

a thinner cut and/or a slower feed rate may be

needed if the material has any of these

characteristics: hardness; gumminess,

sappiness, moisture, paint, varnish and/or

knots. Also, when planing against the grain or

across the grain rather than with the grain, a

shallower cut and/or slower feed rate is

required. Whenever possible, test by planing a

similar piece of scrap material.

Use multiple, progressive cuts to achieve the

total desired depth.

Start with a thin cut. If the plane moves freely

through the workpiece with no excessive load

on the motor, the depth setting can be

increased before the next cut.

When near the desired total depth, re-adjust

the planing depth to a thin setting for the final

cut to obtain a good surface finish.

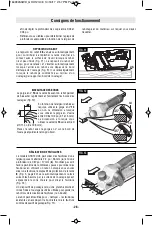

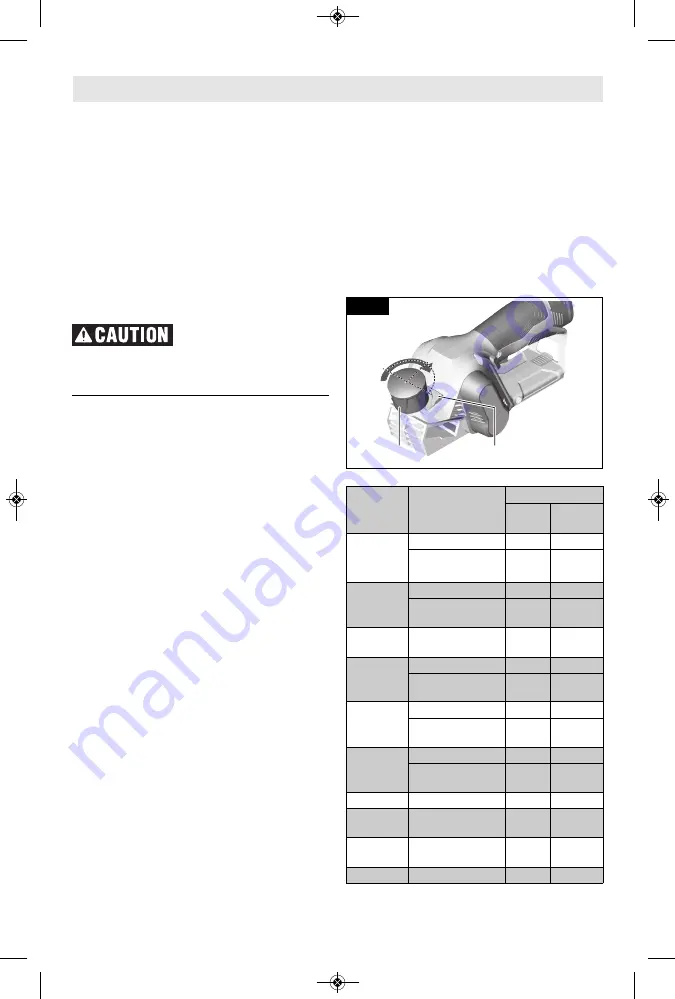

Adjusting the Depth of Cut

-

Turn depth adjustment knob

1

as shown in

Fig. 10 to increase the depth of cut from 0

to .04 inches.

-

To use the extended depth of cut range,

press and hold the Max button

2

and keep

turning the depth knob

1

to set the depth of

cut between .04 and .08 inches.

-

Refer to the table to determine the suitable

depth range based on the planing width

and the material being worked on.

0

0

0

.04

" (1

mm

)

.04" (1mm)

.04

" (1

mm

)

.04

"–.0

8"

.04"–.08"

(1–

2m

m)

(1–2mm)

.04

"–.0

8"

(1–

2m

m)

1

2

FIG. 10

Operating Instructions

Material

Planing Width

Planing Depth

0–.04"/

0–1mm

.04"–.08"/

1–2mm

Softwood

<1.2" / <30mm

•

•

1.2"–1.6" /

30–40mm

•

–

Hardwood

<0.8" / <20mm

•

•

0.8–1.2" /

20–30mm

•

–

Wet

softwood

0–1.6" / 0–40mm

•

–

Plywood

<0.8" / <20mm

•

•

0.8–1.2" /

20–30mm

•

–

Phenolic

resin faced

plywood

<0.61" /<15mm

•

•

0.61–1.2" /

15–30mm

•

MDF sheets

<0.8" / <20mm

•

•

0.8–1.2" /

20–30mm

•

–

Veneers

0.041" / 1mm

•

•

Hardwood

veneers

0.12–0.2" /

3–5mm

•

•

Two-part

filler

0.12–0.2" /

3–5mm

•

•

Cardboard

0.08" / 2mm

•

•

160992A3WD_GHO12V-08 10/16/17 2:57 PM Page 12