English |

17

Bosch Power Tools

2 610 017 516 | (3.11.11)

Protection Guard with Quick Clamp (see figures A–B)

Release the clamping lever

8

. Place the protection guard

4

with the encoding key engaging into the groove on the spindle

collar until the shoulder of the protection guard is seated

against the flange of the power tool, and turn the protection

guard

4

to the requested position. Lock the clamping lever

8

.

f

Adjust the protection guard 4 in such a manner that

sparking is prevented in the direction of the operator.

Note:

The encoding key on the protection guard

4

ensures

that only a protection guard that fits the machine type can be

mounted.

Auxiliary Handle

f

Operate your machine only with the auxiliary handle 3.

Screw the auxiliary handle

3

on the right or left of the machine

head depending on the working method.

Mounting the Diamond Cutting Disc

(see figures C–E)

f

Before any work on the machine itself, pull the mains

plug.

f

When mounting and replacing diamond cutting discs, it

is recommended to wear protective gloves.

f

Diamond cutting discs become very hot during opera-

tion; do not touch them until they have cooled down.

f

Always use a correctly sized diamond cutting disc with

the fitting mounting hole that corresponds with the in-

formation listed in the technical data.

f

Use only diamond-tipped cutting discs. Segmented dia-

mond wheels may only have negative cutting angles

and slots between the segments to a maximum of

10 mm.

Press the spindle lock button

5

to lock the grinding spindle.

f

Actuate the spindle lock button only when the grinder

spindle is at a standstill.

Otherwise, the machine may be-

come damaged.

Loosen and remove the clamping nut

12

with the two-pin

spanner

13

provided.

Clean the grinder spindle

9

and all parts to be mounted.

Pay attention to the dimensions of the grinding tools. The

mounting hole diameter must fit the mounting flange without

play. Do not use reducers or adapters.

When using diamond cutting discs, pay attention that the di-

rection-of-rotation arrow on the diamond cutting disc and the

direction of rotation of the machine (see direction-of-rotation

arrow on the machine head) agree.

Press the spindle lock button

5

to lock the grinding spindle.

Screw on the clamping nut

12

and tighten it with the two-pin

spanner

13

.

f

After mounting the grinding tool and before switching

on, check that the grinding tool is correctly mounted

and that it can turn freely. Make sure that the grinding

tool does not graze against the protection guard or oth-

er parts.

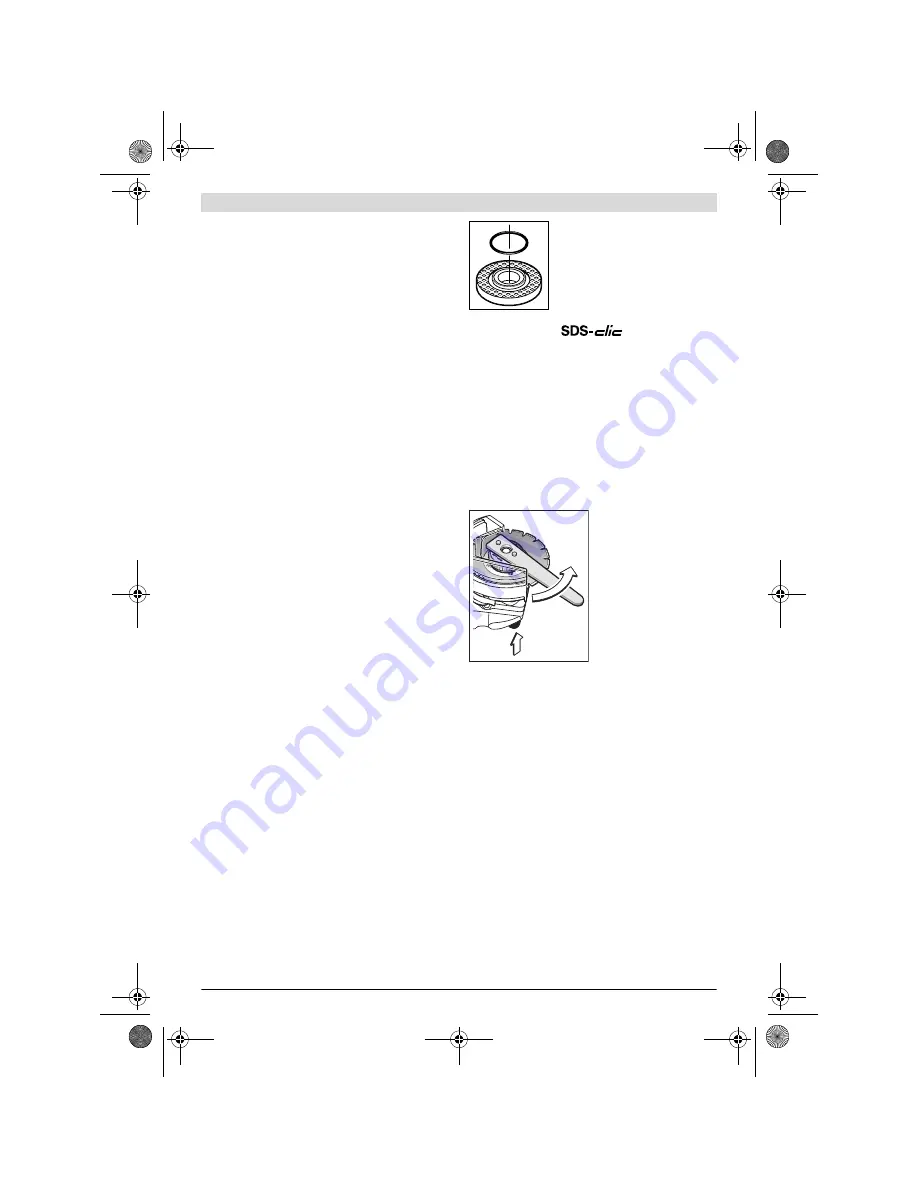

A plastic part (O-ring) is fitted around

the centring collar of mounting flange

10

.

If the O-ring is missing or dam-

aged,

the mounting flange

10

must be

replaced before resuming operation.

Quick-clamping Nut

(see figure E)

For convenient changing of grinding tools without the use of

additional tools, you can use the quick-clamping nut

14

in-

stead of the clamping nut

12

.

f

Use only a flawless, undamaged quick-clamping nut 14.

f

When mounting and replacing diamond cutting discs, it

is recommended to wear protective gloves.

When screwing on, pay attention that the labelled side of the

quick-clamping nut

14

does not face toward the diamond cut-

ting disc

11

; the arrow must point toward the index mark

15

.

To lock the grinder spindle, press and hold the spindle lock

button

5

. To tighten the quick-clamping nut, turn the diamond

cutting disc

11

firmly in clockwise direction.

A properly attached, undam-

aged quick-clamping nut can

be loosened by hand when

turning the knurled ring in anti-

clockwise direction.

Never loosen a tight quick-

clamping nut with pliers. Al-

ways use the two-pin span-

ner.

Insert the two-pin span-

ner as shown in the

illustration.

Mounting the Dry Diamond Core Bit (see figure F)

f

Before any work on the machine itself, pull the mains

plug.

Open clamping lever

8

and remove the protection guard

4

.

Press the spindle lock button

5

to lock the grinding spindle.

f

Actuate the spindle lock button only when the grinder

spindle is at a standstill.

Otherwise, the machine may be-

come damaged.

Screw the dry diamond core bit

16

onto grinder spindle

9

and

tighten it with the open-end spanner

17

.

Dust/Chip Extraction

f

Dust from ceramic tiles (quartz dust) or natural stone (min-

eral dust) can be harmful to one’s health. Contact with or

inhaling the dusts can trigger allergic reactions to the oper-

ator or bystanders and/or lead to respiratory infections.

Certain dusts, such as quartz dust, are considered carcino-

genic. Materials containing asbestos may only be worked

by specialists.

– As far as possible, use a dust extraction system suita-

ble for the material.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

OBJ_BUCH-1502-001.book Page 17 Thursday, November 3, 2011 3:02 PM