6 720 809 134 (2013/09)

Compress 3000 DW FII

8 | About the appliance

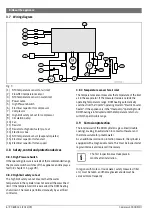

3.7 Wiring diagram

Fig. 5

[1] NTC temperature sensor for air inlet

[2] Flow NTC temperature sensor

[3] NTC temperature sensor in water inlet

[4] Power cable

[5] High Pressure Switch

[6] Electrical capacitor for compressor

[7] Compressor

[8] High limit safety cut-out for compressor

[9] Circulation pump

[10] Fan

[11] Resistor

[12] Resistor for high-limit safety cut-out

[13] Electronics box

[14] NTC temperature sensor (evaporator plates)

[15] Electrical capacitor for fan start

[16] Electrical capacitor for fan speed

3.8 Safety, control and protection devices

3.8.1 High Pressure Switch

If the operating pressure is outside of the recommended range,

the pressure switch switches off the appliance and displays a

fault (

3.8.2 High limit safety cut-out

The high limit safety cut-out ensures that the water

temperature in the cylinder does not exceed the prescribed

limit. If the temperature limit is exceeded, the DHW heating

shuts down. The reset is performed manually by a certified

contractor.

3.8.3 Temperature sensor for air inlet

The temperature sensor measures the temperature of the inlet

air in the evaporator. If the measured value is outside the

operating temperature range, DHW heating automatically

switches from the "Combi" operating mode to "Electric booster

heater". If the appliance is in the "Heat pump" operating mode,

DHW heating is interrupted until the temperature returns to

within the permissible range.

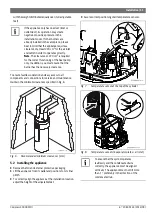

3.9 Corrosion protection

The internal wall of the DHW cylinder is glass-lined (double

coating), making it neutral when in contact with water and

therefore suitable for potable water.

As an additional corrosion protection measure, the cylinder is

equipped with a magnesium anode. This must be inspected at

regular intervals and replaced if necessary.

In regions with more corrosive water, safety measures (filter,

etc.) must be taken, and the magnesium anode must be

serviced more frequently.

The first inspection must take place 6

months after installation.

Summary of Contents for Compress 3000 DW FI Series

Page 29: ...6 720 809 134 2013 09 Compress 3000 DW FII 29 Notes ...

Page 30: ...6 720 809 134 2013 09 Compress 3000 DW FII 30 Notes ...

Page 31: ...6 720 809 134 2013 09 Compress 3000 DW FII 31 Notes ...

Page 32: ...Bosch Thermotechnik GmbH Junkersstrasse 20 24 D 73249 Wernau www bosch thermotechnology com ...