EN

WWW.BORMANNTOOLS.COM

5

• Keep the drums clean. Dirt on drums will cause poor tracking and belt slippage.

• Operate tool with dust collector to keep dust from accumulating.

• The shielded ball bearings in this tool are permanently lubricated at the factory. They require no further lubrication.

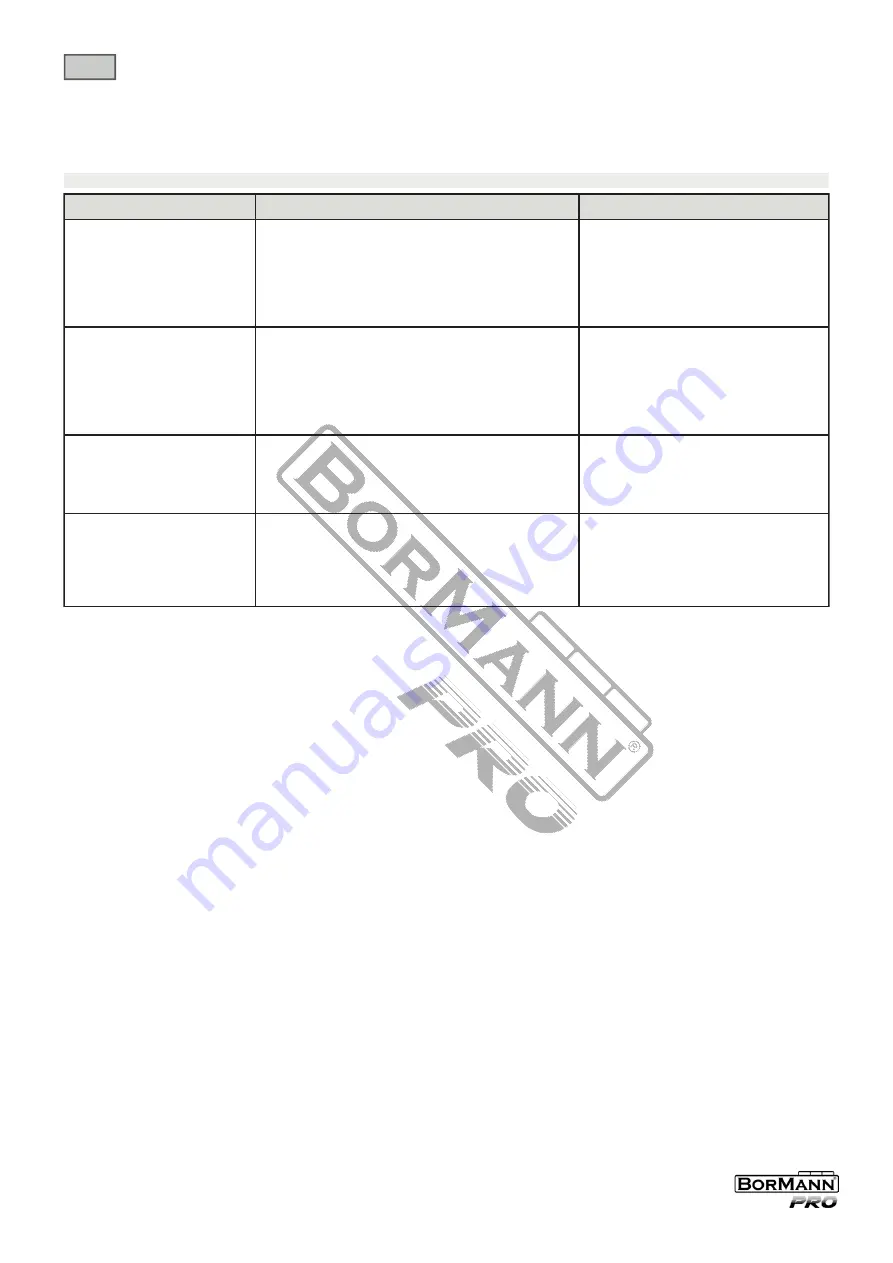

Problems

Probable Cause

Remedy

Grinder won’t start

1. Blown line fuse or tripped circuit breaker

2. Low line voltage

3. Material wedged between wheel and guard

4. Defective switch

5. Defective, blown capacitor

1. If fuse is blown, replace with fuse of proper

size. If breaker tripped, reset it

2. Check power supply for voltage and correct

as needed

3. Turn grinder off and remove material

4. Replace switch

5. Replace capacitor

Excessive vibration

1. Improper mounting of grinder or accessories

2. Grinding wheel out of balance

3. Improper wheel mounting

1. Remount

2. Dress wheel or replace wheel

3. Rotate wheel 90° with respect to its previous

position.

Motor overheats.

1. Excess pressure required to grind material

2. Grinding on side of wheel

3. Motor not turning freely (without power)

1. Dress wheel or replace wheel with one of

proper grit

2. Grind only on face of wheel

3. Clean around wheel and shaft and/or replace

bearings

Fuses are being blown or circuit

breakers are being tripped

1. Overloading due to binding

2. Defective plug

3. Defective cord

4. Defective switch

5. Faulty internal wiring

1. Clean around wheel and shaft and/or replace

bearings

2. Replace plug

3. Replace cord

4. Replace switch

5. Contact authorized Service Center

Troubleshooting

Summary of Contents for 034391

Page 1: ...Art Nr WWW BORMANNTOOLS COM en el BDT1535 v2 1 034391...

Page 10: ......