Hydraulics

Mito

QTH12 English

17

Do not force the bar, during cutting, to bending

effort

3

3

)

)

C

C

h

h

e

e

c

c

k

k

s

s

b

b

e

e

f

f

o

o

r

r

e

e

o

o

p

p

e

e

r

r

a

a

t

t

i

i

n

n

g

g

3.1) Connection to a water supply

The chainsaw is equipped with a water inlet system (figure

8. Connect the chainsaw to a water supply using this system

following those steps:

Connect the water hose (O) to the quick hose

connector (P); Not present

Make sure there is no water leakage;

the maximum pressure of incoming water is 4 bar

(58 PSI);

use just clean water;

4

4

)

)

B

B

a

a

r

r

,

,

c

c

h

h

a

a

i

i

n

n

a

a

n

n

d

d

S

S

p

p

r

r

o

o

c

c

k

k

e

e

t

t

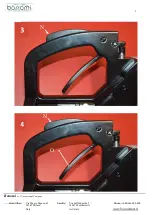

4.1) How to use the bar

the bar (B) needs to be periodically flipped over in

order to wear out eavenly on both sides;

the bar wears out. Usually you need to replace it

every 2 to 3 times you replace a chain;

a correct chain (A) tension allows a longer bar life. See

paragraph

4.2

and image U,V,Z page 10

4.2) How to use the chain. WARNING

Chains usage lead to chain stretching;

An optimal chain tension reduces chain and bar

wear and increases productivity and safety.

Check chain tension before use and stop

periodically during operation to make sure the chain

tension is correct;

An excessive tension leads to higher friction,

reducing cutting performance and increasing bar

and chain wearing;

A loose chain reduces cutting performance and can

lead to the chain to disengage from the bar;

Follow steps in paragraph

4.3) Mounting and

replacing bar and chain

to set the correct chain

tension;

see

also

movie

on:

https://www.youtube.com/watch?v=pX1tBLgFTQU&

t=4s

Check the chain more frequently when the chain is

new since new chains have higher chain stretching.

your hydraulic chainsaw machine is equipped with

a rapid tensioning system called Quick Tensioning

which greatly facilitates the chain tensioning

manoeuvres and thanks to this the chain can work

with the correct tension without the aid of

particularly complicated mechanical manoeuvres,

simply by operating the knob shown in figure 1, T

Pay close attention to the use of this easy and

immediate tensioning system and perform tension

tests before cutting in order to get used to the

tension system

Never perform the tension by turning the knob

shown in figure 1, T during the cutting

The tensioning of the chain must be carried out with

the guide bar pulled out of the cut and with the

chain stopped. Once the ideal tension has been

reached, as described in the following point 4.3

activate the hydraulic saw motion to check if the

tension reached is maintained. If the tension is

optimal, as described in point 4.3, you can continue

with the cutting operations.

The correct maneuver is: Remove the guide bar

from the cut, stop the engine visually check the

conditions of extension of the chain with respect to

the guide bar, (the correct chain tension is shown in

figures U, V, Z in page 10) operate, if necessary,

the tensioning operation of the chain by acting on

the knob of fig. 1, T.

Since the operation is very simple, it is

recommended to avoid the over tension of the

chain, the excessive tension of the chain is not

recommended before starting the cut and can

reduce the chain life

The equipment allows tensioning and give up the

chain with a simple screwing or unscrewing

operation of the indicated knob,

it is therefore the

operator's

responsibility

to

realize

that

excessive tension can cause damage to the

equipment as well as to people and damage the

chain by cracking.

We invite any operators to take good knowledge of

the use of this easy system that on the one hand is

very effective in terms of operator fatigue and

cutting times on the other hand if used with abuse

can induce the chain to work in conditions of

overload and permanently damaging it,

thus

creating a dangerous condition.

4.3) Mounting and replacing bar and chain

Before mounting or replacing the bar (B) or the

chain (A) make sure the chainsaw is unplugged (M)

and the power pack is switch off. Do this operation

in a safe place, use protective gloves and place the

product on a stable

surface.

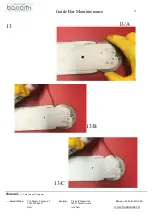

Installing Chain (A) See figure 10, page 10, 1, and follow

these

steps:

or

link

to

the

movie

https://www.youtube.com/watch?v=pX1tBLgFTQU&t=4s

1.

Unscrew and remove the 2 side cover screw (11/A)

2.

Remove the cover (11/B);

3.

loosen the 11/A nut on the back of the machine the guide

bar will be released and can slide back and forth and is

free to change,

4.

Using the, T tension knob. Return the sprocket to the

initial position from 11C to11C1, page 7

5.

Positioning the guide bar towards the sprocket 10/D in

order to create the necessary space for inserting the

chain,

6.

Easily extract the old chain,

7.

Insert the new chain on the guide bar 10/A and wind the

chain around the 10/B guide bar head bearing, to have

the chain saving at the back of the sprocket 10/G,

8.

Install the chain on the sprocket proper position 10/C,

please note

the reverse chain made specifically for this

machine has a sense of cutting, see fig Y page 10, make

sure not to install the chain in the opposite direction,

9.

If you install the chain in the wrong direction

compromises the functionality of the same as well as

damage it irreparably,

10.

Repeat reverse step from point 4.3 to 4.1 to fix not

permanently the cover.

11.

Pull the guide bar by positioning the chain in a manual

tension position, see page 8, Fig.10G to 10H and than

Screw and fix the 2 nut 11/A on the back of the machine

body and secure the guide bar to the machine body fig

10/I