Hydraulics

Mito

QTH 12 English

16

d) Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and

any other condition that may affect the power

tools operation.

lf damaged, have the power tool

repaired before use. Many accidents are caused by

poorly maintained power tools.

e) Keep cutting tools sharp and clean.

Properly

maintained cutting tools with sharp cutting edges are

less likely to >>>> and are easier to control.

f) Use the power tool, accessories and tools etc., in

accordance with these instructions and in the

manner intended for the particular type of power

tool, taking into account the working conditions

and the work to be performed.

Use of the power

tool for operations different from intended could

result in a hazardous situation.

5)

Service

e)

Have your power tool serviced by a qualified

repair person using only identical replacement

parts.

This will ensure that the safety of the power

tool is maintained.

2

2

)

)

S

S

a

a

f

f

e

e

t

t

y

y

r

r

u

u

l

l

e

e

s

s

f

f

o

o

r

r

y

y

o

o

u

u

r

r

c

c

h

h

a

a

i

i

n

n

s

s

a

a

w

w

2.1) Water supply: Safety rules

In order to run properly, the chain needs to be

cooled by water.

2.4) Checks and precautions to avoid structural

damage and damage to a building

2.2) Checks and precautions to avoid structural damage

and damage to a building. DANGER

Before operating, talk to the construction manager or the

planner in order to make sure that cutting doesn’t:

damage the structure of the building and change

the structural characteristics of the construction;

damage any water or gas pipeline or any electric

mains.

DANGER

Particularly care if presence of gas

pipeline, cutting iron sparks is present and can be a

comburent for the gas

2.3) Checks and precautions to avoid damage caused

by the fall of the cut out work piece. DANGER

before operating, make sure that the possible falling

of the cut out work piece doesn't make any

damage. In any case, secure the area where the

work piece can fall and signal the danger;

if the possible fall of the cut out work piece can

damage anybody or anything, make sure to have a

proper system in place to secure it safely.

2.4) Fastening the work piece and size of the work piece

if you are operating on a block not part of a

structure, fasten it in order to prevent its movement.

Prevent the work piece from shifting, moving or

falling when you are cutting.

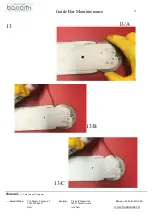

2.5) Suitable Bars and Chians

Use bars and chains for wet cutting. Bars and chain

for concrete, reinforced concrete, stone, are

suitable for your product. Your product is not

suitable to cut wood, plastics, metals (except

reinforcing bars in concrete).

Use only bars and chains provided by BONOMI

or authorized dealer.

2.6) Bars and Chains not to be used

Do not use bars and chains other than the ones

prescribed by BONOMI. Do not use chains for

wood, tungsten carbide chains or chains for

masonry.

Chains for wood or masonry generate a

kickback effect when plunging.

2.7) Protective devices

Before operating make sure to wear all safety devices listed

below:

Always

wear safety

goggles

Always

wear safety

gloves

Always

wear ear

protection

Always

wear safety

shoes

2.8) Other safety directions. WARNING

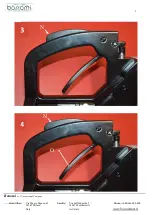

Keep handles (pointed with H and F in figures)

dry and clean. Make sure there is no oil or

grease on them.

Greasy or wet handles can lead

to lose control of the chainsaw.

Make sure to firmly grip the product using both

hands on handles (fig. 5).

F

irmly hold the product

with both hands till the chain has come to a

complete stop.

When storing or transporting the product make

sure the protecting cover (not present) is on the

bar (B) and chain (A)

.

When operating, keep proper footing and

balance for a full control of the product.

Improper footing and balance, operating on ladders

or on unstable structure can lead to serious injury

or death.

When operating do not excessive stretch out

your arms and do not perform cut higher than

your shoulders.

Arms stretched too far out or cuts

above shoulder height can lead to loss of control of

the chainsaw.

Keep the chain sharp (see “Operating tips”

paragraph).

A not dull chain leads to an excessive feed by the

operator and this can lead to lose control of the

product.

Do not use the product if the cover (D), the front

panel (G), the slurry protector (I) or any other

protection devices is damaged or not properly

working.

Those devices prevent to get in contact

with moving parts and to protect the operator from

slurry and debris.

Do not use the product if chain, main sprocket

and/or bar are damaged.

When performing vertical cuts, do not operate

using the product upside down (fig. 18).

Water

and debris can hit the operator and can wrongly

flow over the product leading to a possible danger.

For this reason do not perform overhead cuts!!!

Do not place the bar and chain in a previously

made cut performed with a narrower chain (less

than 6 mm).

This can lead to a kickback.

Do not force the bar, during cutting, to torsion

effort