22

AGL-STOV0-01SV0-05

06/12

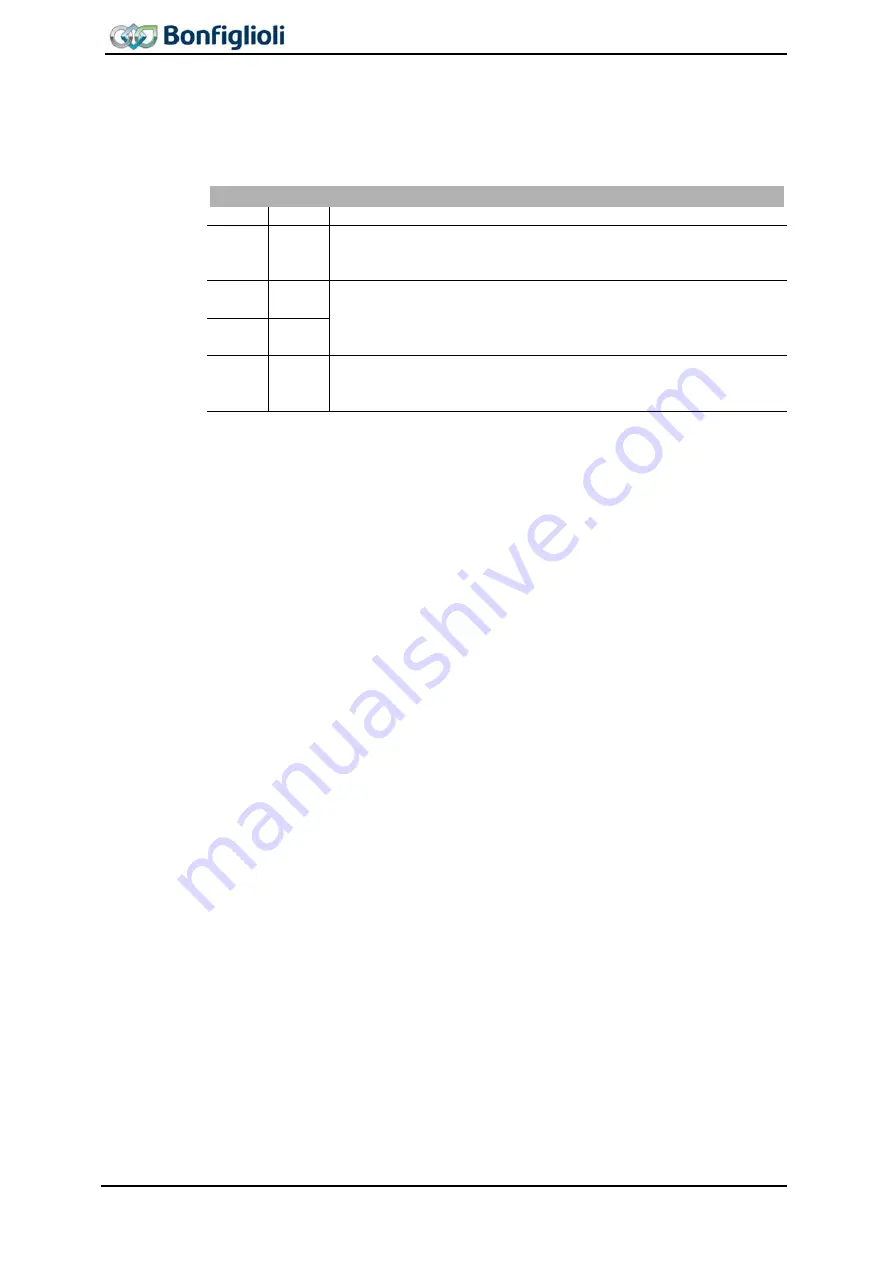

Truth table

In the truth table, the states of the safety-relevant inputs STOA and STOB for activa-

tion and deactivation of the safety function STO are listed.

Truth table

STOA STOB

Description of state

0 0

Safety function “Safe Torque Off” (STO) has been triggered. The

frequency inverter signals no error in STO function. The inverter

release is interrupted.

0 1

STO is triggered. Monitoring for error in frequency inverter or ex-

ternal circuitry (5-second monitoring). After 5 seconds, an error is

signaled.

The inverter release is interrupted.

1 0

1 1

STO is not triggered. Release for operation.

Only in this state starting signals are accepted by the frequency

inverter and lead to a switching of the modulation.

5-second monitoring

It will be checked if the two inputs STOA or STOB are switched on within an interval

of less than 5 sec for requesting the release of the frequency inverter output stages.

If function STO is triggered by removing one of the signals from inputs STOA or

STOB, the status changes to “STO triggered” and the output stage is inhibited. In this

state the monitoring function checks, that during the next 5 seconds the second input

is switched off. If this has not been done within 5 s after occurrence of this state, an

error is triggered (5-second monitoring).

−

Different signal states on inputs STOA or STOB start the 5-second monitoring

−

Within 5 seconds, the same signal must be present of both inputs, otherwise an

error will be signaled (F1205)

−

If the STO function is triggered on one channel, in the next following 5 s the STO

function must be triggered on both channels.

The error F1205 can be acknowledged using the Fault reset to reset the drive.

Behavior of frequency inverter after start

−

Initialization

−

Monitoring for release request (5-second monitoring)

−

Preparation of release (check of stop paths)

−

Release of frequency inverter

Behavior of frequency inverter in the case of an error

−

Switch off of IGBT in power output stage by disconnection of optocoupler supply

voltage

−

Suppression of control pulses of IGBT

−

Setting of error bit with possibility of transfer to overriding controller

−

Setting of digital output for error message

−

Release of digital input for error acknowledgement.