11

which can be adjusted between 4 seconds to 99 seconds. Herein, to press

▲

or

▼

key to change the retaining

time and press ENTER to confirm the selected value.

(7) When the cursor comes to the item “Magnification”, press ENTER to preset the magnification ratio which can

be changed over between Auto, 1X and 2X. Herein, to press

▲

or

▼

key to select the expected magnification

ratio and press ENTER to confirm the selection.

If “Auto” is selected, the magnification ratio will be changed over automatically. If others are selected, the selected

magnification ratio must be the same as that actually used. Otherwise, the measured results are incorrect.

(8) When the cursor comes to the item “Test force”, to press ENTER and preset the test forces by pressing

▲

or

▼

key from the following: 187.5kgf, 250kgf, 500kgf, 750kgf, 1000kgf, 3000kgf. At the end, press ENTER to

confirm the selection.

(9) When the cursor comes to the item “Diameter”, to press ENTER and preset the diameter of indenter by pressing

▲

or

▼

to choose from

φ

10mm,

φ

5mm and

φ

2.5mm, and press ENTER to confirm the selection.

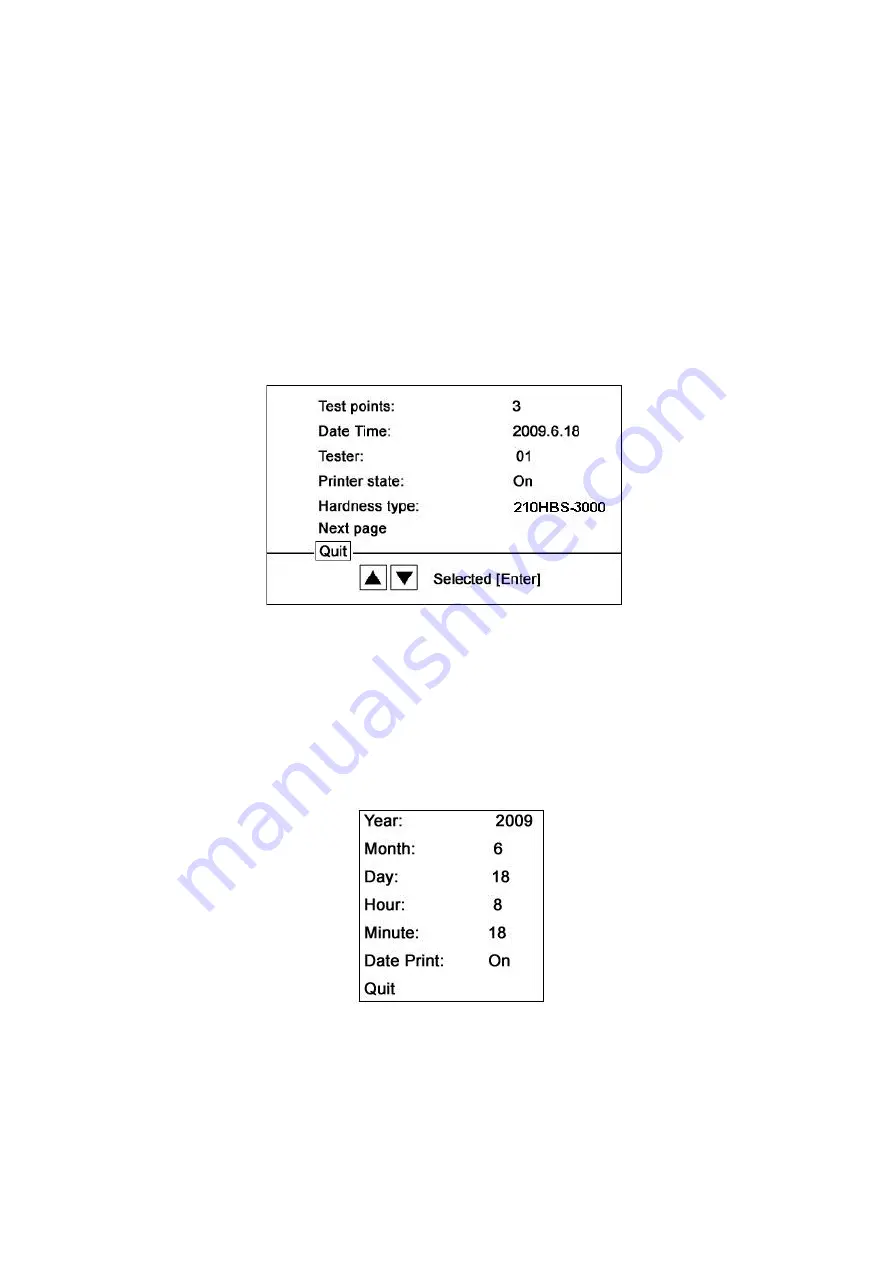

(10) When the cursor comes to the item “Next page”, press ENTER to enter the menu shown in Fig-10.

(11) When the cursor comes to “Quit”, to press ENTER to exit the preset menu and return to the interface of Fig-8.

Fig-10 Menu interface

(12) When the cursor comes to the item “Test points”, to press ENTER to preset whether or not to carry out data

statistics whose range is from 1 to 99. If 1 is selected, no statistics will be done, i.e. to print out the test results of

each test. If the figure more than 1 is selected, it will print out the test results of each test and the average of the test

results. The number of statistical test points can be selected by pressing

▲

or

▼

key.

(13) When the cursor comes to the item “Date Time”, to press ENTER to preset the date of test and a small window

will be shown as Fig-11. For details, please refer to Article (19).

(14) When the cursor comes to the item “Tester”, press ENTER to preset the code of operator by pressing

▲

or

▼

key to select from 1 to 99.

Fig-11 Menu interface

(15) When the cursor comes to the item “Printer state”, press ENTER to preset the printer to be On or Off.

(16) When the cursor comes to the item “Hardness type”, press ENTER to preset the type of hardness and

interchange between different hardness and tensile strength. A small window will be shown as Fig-12. For details,

please refer to Articles (20) ~ (22).