11

Lowes.com

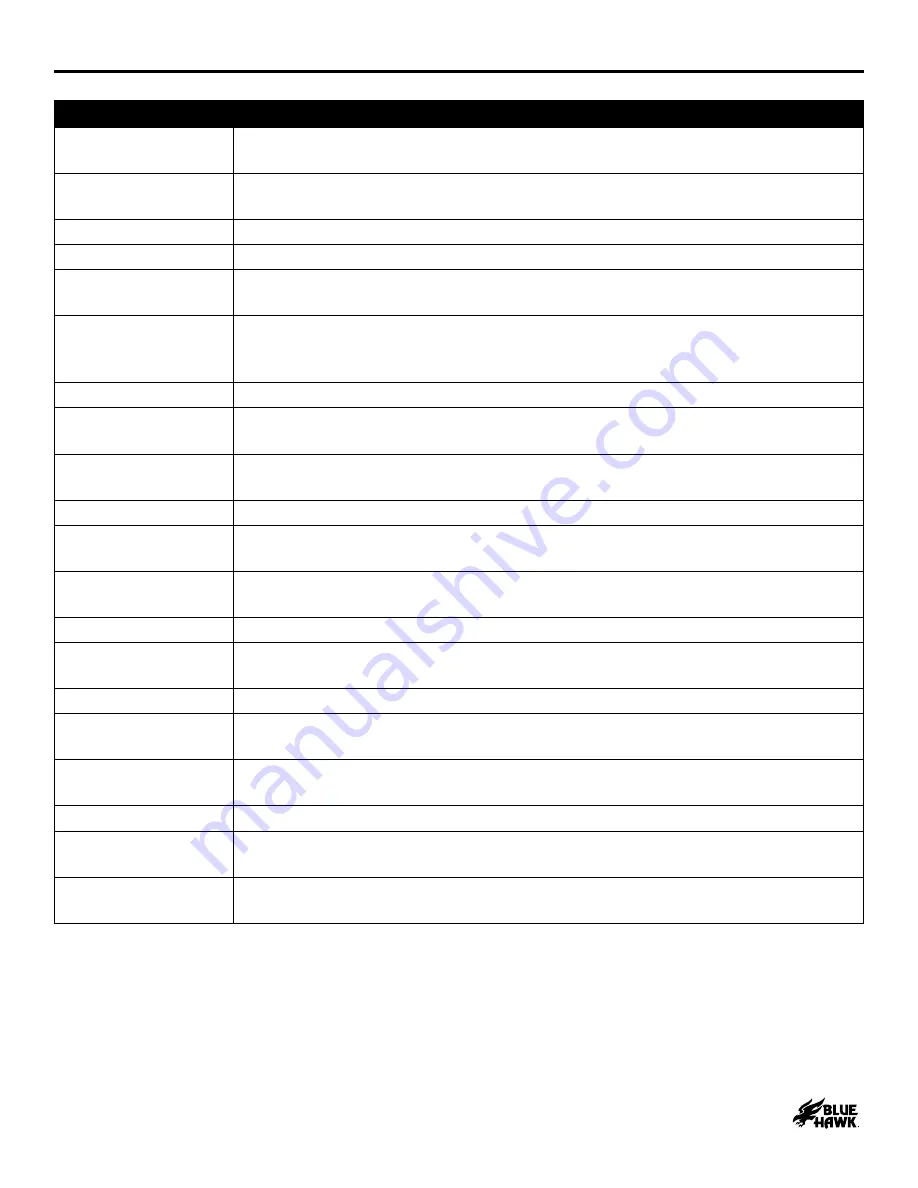

GlOssARY OF TERms FOR wOOdwORKInG

TERm

dEFInITIOn

Bevel Cut

A cutting operation made with the blade at any angle other than 90° to the

miter table.

Chamfer Cut

A cut removing a wedge from a block of wood so that the end (or part of the

end) is angled at other than 90°.

Compound-Miter Cut A cut made using a miter angle and a bevel angle at the same time.

Cross Cut

A cutting or shaping operation made against the grain of the workpiece.

Dado Cut

A non-through cut that produces a square-sided notch or trough in the

workpiece (requires a special blade).

Freehand Cut

Performing a cut without using a fence, miter gauge, fixture, work clamp, or

other proper device to keep the workpiece from twisting or moving during the

cut. Freehand cuts are dangerous and should be avoided.

Gum

A sticky, sap-based residue from wood products.

Kerf

The material removed by the blade in a through cut or the slot produced by

the blade in a non-through or partial cut.

Kickback

A hazard that can occur when the blade binds or stalls, throwing the

workpiece back toward the operator.

Leading Edge

The end of the workpiece pushed into the tool first.

Miter Cut

A cutting operation made with the blade at any angle other than 90° to the

fence.

Non-Through Cuts

Any cutting operation where the blade does not extend completely through

the thickness of the workpiece, like a dado cut.

Resin

A sticky, sap-based substance that has hardened.

Revolutions Per

Minute (RPM)

The number of turns completed by a spinning object in one minute.

Ripping or Rip Cut

A cutting operation along the length of the workpiece.

Saw-Blade Path

The area over, under, behind, or in front of the blade, as it applies to the

workpiece. The area that will be or has been cut by the blade.

Set

The distance that the saw blade tooth is bent (or set) outward from the face of

the blade.

Spindle

The shaft on which a blade or cutting tool is mounted. Also called the arbor.

Through Sawing

Any cutting operation where the blade extends completely through the

thickness of the workpiece.

Workpiece or

Material

The item on which the cutting operation is being done. The surfaces of a

workpiece are commonly referred to as faces, ends, and edges.