2

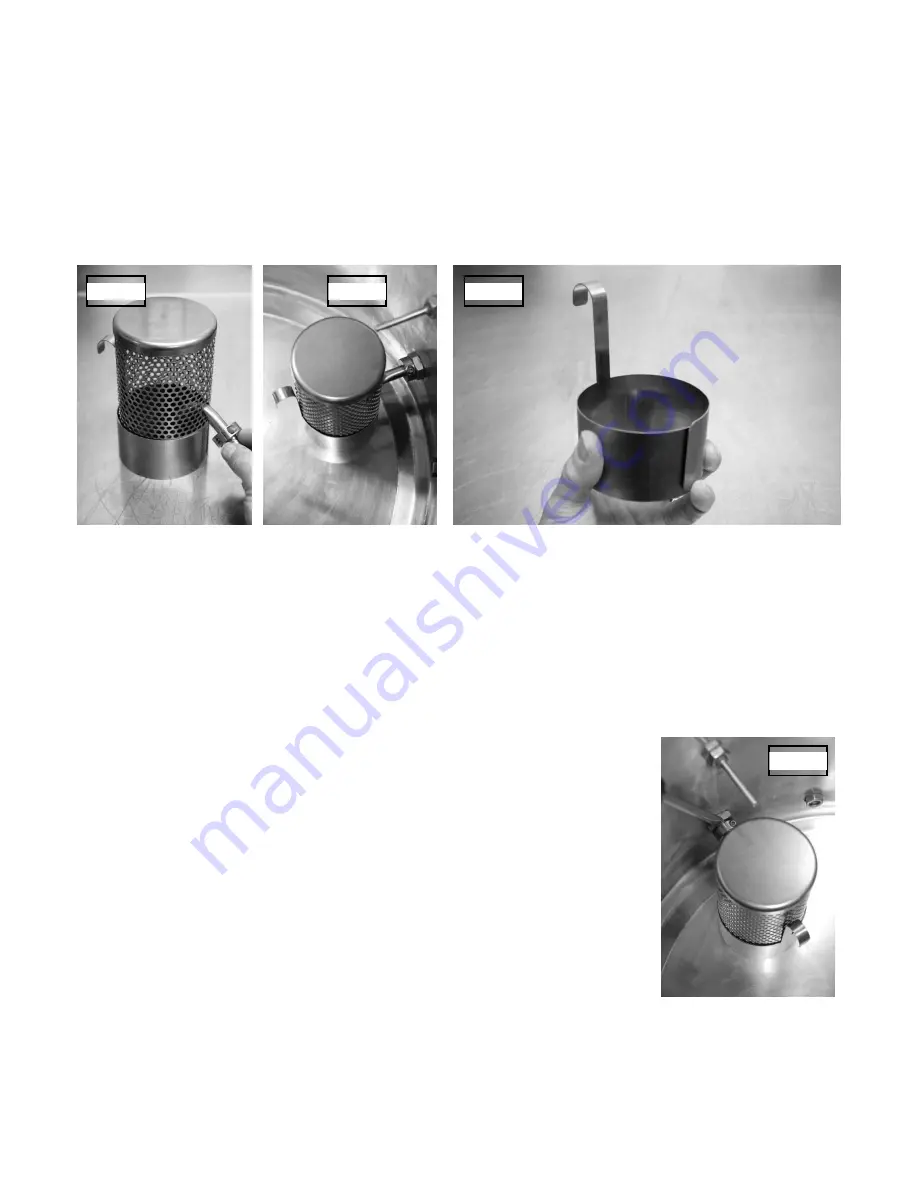

Fig. 2

Fig. 3

Fig. 4

Installation in a BoilerMaker

tm

brew pot:

To install the HopBlocker

tm

in your BoilerMaker

tm

brew pot, simply remove the dip tube and place it in

the hole in the side of the HopBlocker

tm

as show in Fig 2. Note that the gap in the shield faces the drain

fitting (the finger pull faces the center of the pot). Then simply insert the tube into the drain fitting as

shown in Fig 3. It is helpful to lubricate the tube with a bit of water to make insertion easier.

Important:

ensure that the shield grips the sides of the screen sufficiently so that it will hold itself up

when moved to the top of the screen. If it does not, gently bend the shield in slightly so it grips more

firmly as shown in Fig 4.

Installation into a non-Blichmann Engineering

TM

pot:

You will need to provide a ½” diameter dip tube in your pot with a fairly sharp 90 degree bend 3” above

the bottom of the pot. The bottom of the dip tube should sit above the bottom of the pot about

3/8”

to

½”.

Since you cannot rotate the tube to install it, you will need to provide a compression or flare fitting

adapter on the inside of the pot to accommodate installation of the HopBlocker

TM

. The closer you can

get the HopBlocker

TM

to the sidewall of the pot the better the performance will be. For kegs, you will

need to center the HopBlocker

TM

in the middle of the keg so that it sits flat. However, this will negatively

affect the performance of the filter.

Removal in a BoilerMaker

TM

brew pot:

To remove the HopBlocker

TM

in your BoilerMaker

TM

brew pot we recommend

using a flat blade screw driver between the shaft collar and the drain fitting

(ref Fig 5) to get the tube out of the o-ring seat. You only need to open a gap

of about 1/8” to pop the t

ube out of the grip of the o-ring and from there it

can be removed by hand by pulling straight out.

Fig. 5