COMMISSIONING

THE ORGANISATION RESPONSIBLE FOR THE COMMISSIONING SHALL BE RESPONSIBLE

FOR PROPER MOTOR PHASING AND STARTING PATTERN SELECTION.

• After fan starting make sure that the electric motor rotates properly without undue vibration and abnormal noise.

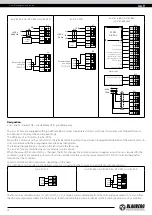

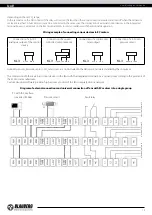

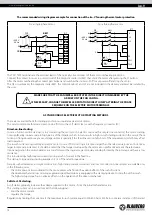

• Make sure that the fan impeller rotates in the direction marked by the arrow on the fan casing. If necessary, change the rotation

direction of the impeller by reversing the phase sequence (for a three-phase motor) or by rewiring according to the wiring diagram

located inside the terminal box (for a single-phase motor).

• Make sure that the fan energy consumption complies with the value given on the equipment nameplate and check the motor for

overheating.

• The phase current should be checked once the fan reaches the rated operating conditions.

• Do not switch the fan on and off several times without pauses as this may result in damage to the winding or insulation due to

overheating.

DURING STARTING THE IN-RUSH CURRENTS OF THE FAN MAY SEVERAL TIMES EXCEED

THE RATED VALUES.

SEE “ASYNCHRONOUS ELECTRIC MOTOR STARTING METHODS” IN THE “CONNECTION

TO POWER MAINS” SECTION

TECHNICAL MAINTENANCE

DISCONNECT THE UNIT FROM POWER SUPPLY BEFORE ANY MAINTENANCE

OPERATIONS!

ENSURE THAT THE UNIT IS SWITCHED OFF FROM THE SUPPLY MAINS BEFORE

REMOVING THE GUARD.

• The technical maintenance includes periodic cleaning of the surfaces from accumulated dust and dirt.

• When carrying out fan maintenance, it is necessary to partially disassemble it in order to access contaminated parts of the fan. To do

this, you need to unscrew the screws and remove the cover from the casing. The impeller blades require thorough cleaning once in

6 months.

• Use a soft dry cloth, brush or compressed air to remove dust.

• Carry out wet cleaning using warm water and a mild household detergent. Protect the electric motor against liquid ingress. Do not

immerse the unit in water!

• Do not use aggressive solvents, or sharp objects as they may damage the impeller.

www.blaubergventilatoren.de

iso-V

16