104-A00 Page 12/16

MAINTENANCE

Hazardous

machinery can

cause serious

personal injury.

Failure to stop the pump before

adjusting the shaft packing can cause

severe personal injury.

9.

PACKING ADJUSTMENT

Packing must be properly adjusted to prevent overheating.

a. While the liquid is being pumped, check for leakage

from the stuffing box. STOP the pump and uniformly

tighten the packing follower stud nuts (18) 1/4 turn at

a time to reduce leakage.

b. Restart the pump and check the stuffing box

temperature several minutes after each adjustment

for signs of overheating.

c.

Check the packing again after 20-30 minutes of

running the pump, and readjust if necessary.

NOTE:

Some leakage is desirable to lubricate the

packing, but in some cases is unacceptable,

depending on the application.

10. BLACKMER TRIPLE-LIP SEAL (if equipped)

On pumps equipped with a Blackmer triple-lip seal, refer to the

separate literature accompanying the triple-lip seal for

installation instructions.

11. COMMERCIAL MECHANICAL SEAL (if equipped)

On pumps equipped with a commercial mechanical seal, refer

to the separate literature accompanying the mechanical seal

for installation instructions.

12. SHAFT SUPPORT BEARING (SNP3A if equipped)

a. Screw the short threaded ends of the two hex studs

(106E) firmly into the holes in the head.

b. Place the bearing flange (106) on the studs and tighten

the locknuts (106A).

c. Slide the bearing and lock collar (106B) on the shaft

until it is firmly seated in the bearing flange (106A).

d. Push inward on the bearing and lock collar (106B)

while turning the lock collar by hand in the same

direction as the shaft rotation.

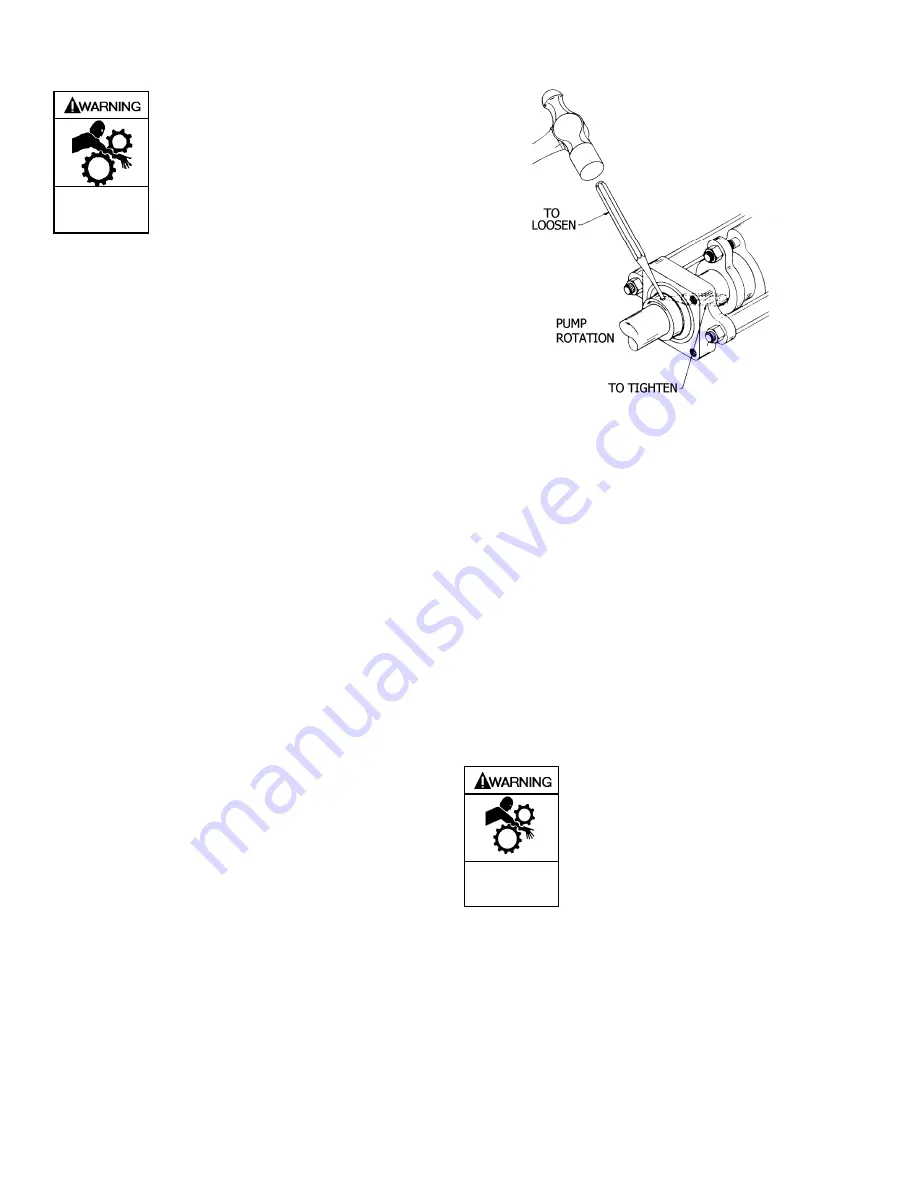

e. Lock the collar to the shaft with a punch in the same

direction as the shaft rotation. See Fig. 11.

f. Bolt on the flange cover (106C).

g. If the shaft does not turn freely, loosen the lock collar

and make sure the bearing is firmly seated in the

bearing flange (106). Re-tighten the lock collar.

Figure 11 – Shaft Support Bearing Lock Collar

13. RELIEF VALVE ASSEMBLY (if equipped)

a. Insert the valve (9) into the relief valve body (6) with

the fluted end inward.

b. Install the relief valve spring (8) and spring guide (7)

against the valve.

c.

Attach a new relief valve gasket (10) and the valve

cover (4) on the relief valve body (6).

d. Screw the relief valve adjusting screw (2) into the

valve cover until it makes contact with the spring

guide (7).

e. Install the relief valve cap (1) and gasket (88) after

the relief valve has been precisely adjusted.

NOTICE:

The relief valve setting MUST be tested and

adjusted more precisely before putting the pump

into service. Refer to "Relief Valve Setting and

Adjustment"

14. Reinstall coupling, shaft key, and coupling guards.

Do not operate

without guard in

place.

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

15. Refer to “Pre-Start Up Check List” and “Start Up

Procedures” sections of this manual prior to pump

operation.

Summary of Contents for SNP1.25

Page 15: ...104 A00 Page 15 16 NOTES...