701-B00 page 6/12

INSTALLATION

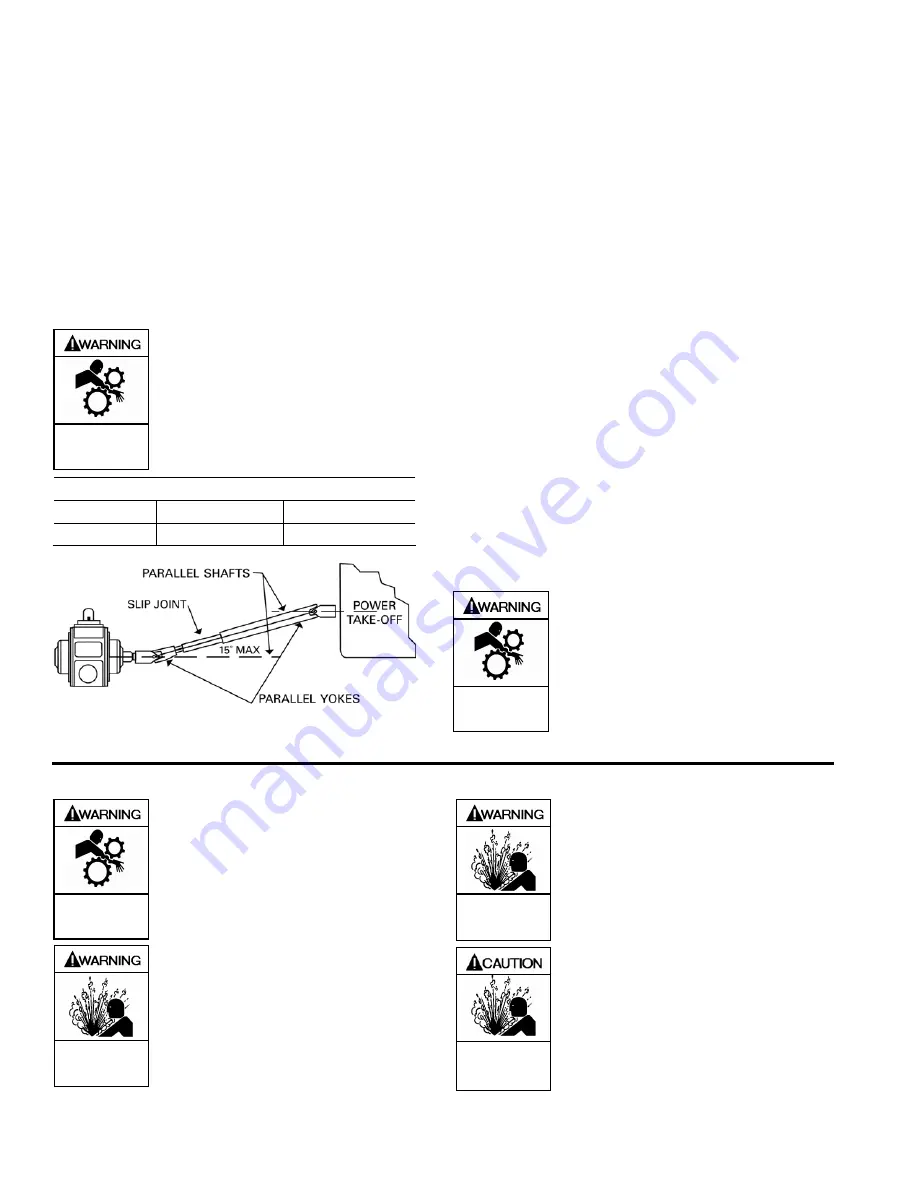

5. The yokes of the universals at both ends of the jack

shaft must be parallel and in phase.

6. The maximum recommended angle between the jack

shaft and the pump shaft is 15 degrees. See Table 1.

Failure to follow any of these guidelines may result in a

gallop or uneven turning of the pump rotor, which will in turn

cause a surging vibration to the liquid stream and piping

system. Contact the supplier of the drive line components for

specific design assistance.

PTO driven units MUST contain speed control devices to

prevent pump speeds above the maximum RPM

specifications, regardless of the truck engine unloading

speeds. Should fluid delivery be appreciably less than

expected, see the "General Pump Troubleshooting" section.

Do not operate

without guard

in place

A drive shaft guard between the pto

and pump must be provided to prevent

personal injury, property damage, or

death.

Tabel 2 - Angle of Drive Shaft

1

o

through 5

o

6

o

through 10

o

11

o

through 15

o

Very Good

Good

Fair

NOTE:

A Drive Shaft Guard between the pump and the

PTO MUST be provided.

(Not shown)

Figure 7 – PTO Drive

HYDRAULIC DRIVE

Truck mounted pumps may also be driven hydraulically.

Hydraulic motors should be well supported with their shafts

parallel to the pump shaft in all respects. Blackmer provides an

optional close-coupled hydraulic motor adapter. The adapter

provides for straight alignment of a hydraulic motor drive

through a solid coupling connected to a straight key pump

shaft. This coupling connection requires grease lubrication

every three months at

minimum

. Refer to the "Lubrication"

section of this manual.

Hydraulically driven units MUST contain speed control devices

to prevent pump speeds above the maximum RPM

specifications, regardless of the truck engine unloading

speeds. Should fluid delivery be appreciably less than

expected, see the "General Pump Troubleshooting" section.

PUMP ROTATION

NOTICE:

Confirm correct pump rotation by checking the pump

rotation arrows respective to pump driver rotation.

TO CHANGE PUMP ROTATION

Blackmer 2 and 3” CRL pump models are equipped with a

double ended rotor and shaft, enabling them to be driven from

either shaft end. To change rotation, rotate the pump 180

degrees so that the opposite shaft becomes the driven shaft.

The shaft protector (186) MUST be mounted over the non-

driven shaft end.

Do not operate

without guard

in place

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

OPERATION

Do not operate

without guard

in place

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

Hazardous pressure

can cause serious

personal injury or

property damage

Failure to relieve system pressure prior

to performing pump service can cause

serious personal injury or property

damage.

Systems with meters will still

be pressurized even after the hose is

emptied

Hazardous pressure

can cause serious

personal injury or

property damage

Disconnecting fluid or pressure

containment components during pump

operation can cause serious personal

injury or property damage.

Hazardous pressure

can cause personal

injury or property

damage

Pumps operating against a closed valve

can cause system failure, personal

injury and property damage