701-B00 page 5/12

INSTALLATION

V-BELT DRIVE

For installation of Blackmer V-belt units, first mount the pump

and the motor base to the unit base. Do not fully tighten the

motor mounting bolts until properly installing and adjusting the

belts as follows:

1. Wipe the cone surface of the pump QD hub (152A) and

the inside of the pump sheave hub with a clean cloth

moistened with a light grade of machine oil. This will

allow for a more uniform draw and prevent the cone

surfaces from “freezing” before being tightened.

2. With the pump shaft key (35) in place, align the key seat

and slide the QD hub (152A) on the shaft, flange end

first. Slide the large end of the sheave (152) bore over

the taper on the QD hub. Insert the three sheave

capscrews (152G) through the clearance holes in the

sheave, and start them into the tapped holes of the QD

hub (152A). Repeat this procedure to assemble the

motor QD hub (152E) and sheave (152D).

3. To install the belts (181), shorten the center distance of

the drive by moving the motor towards the pump, until the

the belts can be put on the sheaves (152 & 152D) without

forcing.

4. Align the sheaves so that the faces are parallel, then

snug up the sheave capscrews (152C & G).

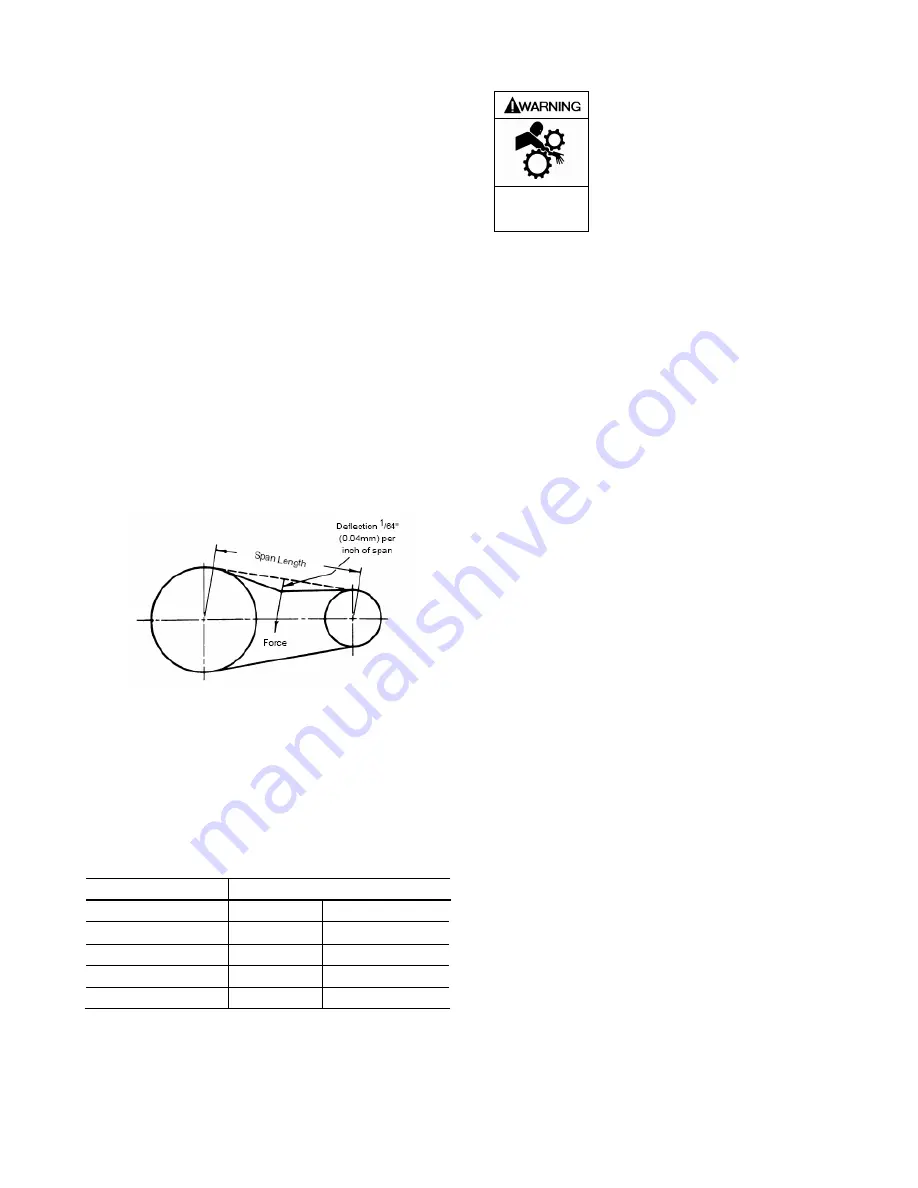

5. Measure the span length as shown in Figure 6.

Figure 6 – V-Belt Adjustment

6. Adjust the motor base (183) and apply a specified force

(refer to Table 1) against the belt, at the center of the

span, so that the belt is deflected 1/64 inch (0.04 mm) for

every inch (25.4 mm) of span. For example, the

deflection of a 20 inch (508 mm) span would be 20/64 or

5/16 inch (7.9 mm). The force required should be within

the range given in Table 1 for a properly tensioned drive.

A new set of belts should be initially tensioned to the

upper limit.

Table 1 – V-Belt Deflection

SMALL SHEAVE

BELT DEFLECTION FORCE

OUTSIDE DIAMETER

Minimum

Maximum

2.5

" to

4.5

"

3.0 lbs.

4.75 lbs.

(63.5 mm to 114.3 mm)

(1.4 kgs.)

(2.2 kgs.)

4.75

" to

7.0

"

4.0 lbs.

6.0 lbs.

(120.7 mm to 177.8 mm)

(1.8 kgs.)

(2.7 kgs.)

7. Check again to ensure the sheaves (152 & 152D) are

parallel, then tighten the sheave capscrews (152C &

152G), the motor mounting nuts (183B) and the adjusting

screw locknut (183B).

8. Assemble the belt guard (182) and the belt guard brace

(182A) to the unit base (32).

Do not operate

without guard

in place

Operation without guards in place can

cause serious personal injury, major

property damage, or death.

9. Check the belt tension after 24-48 hours of operating.

Recheck the tension periodically and tighten the belts as

required. DO NOT overtighten belts. Inspect belts

periodically for signs of excessive wear, and replace as

required.

V-BELT DISASSEMBLY

1. Remove the belt guard (182) and the guard base (182A).

2. Loosen the adjusting screw locknut (183B) on the motor

base (183) and the motor mounting nuts.

3. Ease the tension on the belts (181) by moving the motor

towards the pump to shorten the center distance of the

drive. Remove the belts by sliding them over the sheaves

(152 & 152D). DO NOT force the belts over the grooves.

4. To remove the sheave from the hub, first remove the

three sheave capscrews (152C or 152G). Then screw

two of the capscrews into the threaded holes in the

sheave hub (152A or E). If the cone grip is hard to break

loose, tap the end of the shaft or the QD hub with soft-

faced mallet while maintaining pressure on the screw.

5. The QD hub should slide smoothly off the shaft. If it is

tight on the shaft, gently pry it loose with a screwdriver or

a small wedge placed in the split part of the flange.

Refer to Blackmer V-Belt Parts List and Instructions for

V-belt drive and guard part numbers.

PTO DRIVE

The pump may be driven by a power take-off through

universal joints. When using universal joints, a splined slip

joint, properly lubricated, must be used on the connecting jack

shaft to prevent end thrust on the pump shaft.

A proper drive line must be installed to avoid excessive wear,

vibration and noise (see Figure 7 and Table 2).

General guidelines to follow for proper pump drive:

1. Do not use square slip joints.

2. Use the least number of jack shafts as is practical.

3. Use an even number of universal joints.

4. The pump shaft and power take-off shaft must be parallel

in all respects. Use an angular level measuring device to

ensure the PTO and pump shaft are parallel to each

other. If necessary, the pump can be shimmed to correct

any misalignment. The PTO shaft coming off at the

transmission does not need to be perfectly horizontal as

long as the pump is shimmed to have its shaft parallel in

all respects to the PTO shaft.