Italia Star Com Due S.R.L.

www.italiastar.ro

004/021.433.03.27

109

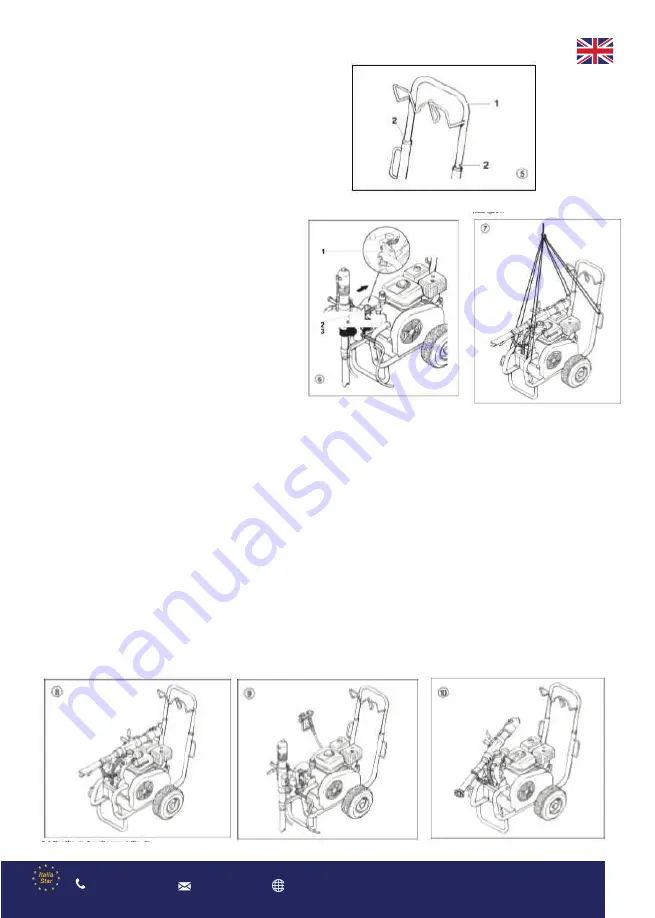

3.9 Transport Handle Pull out the handle (fig. 5, item 1) until it

will come no further. Push in the snap buttons (2) on the sides

of the handle and insert the handle.

3.10 Transport in vehicle Push locking pin (fig. 6, item 1) in the

swivel mechanism (2) for the material feed pump (3) and

swivel it to a horizontal position. Ensure that the locking pin

locks. Roll the high-pressure hose over the hose rack on the

handle. Secure the unit with a suitable fastening.

3.11 Crane transport Hanging points for crane straps or ropes,

see figure 7.

4. Starting operation 4.1 Swivel mechanism of the material feed pump

Be careful, as the moving parts of the swivel mechanism can crush fingers and feet.

1. Transport position (fig. 8) Transport unit only when the material feed pump is in the horizontal position. Swiveling

the material feed pump to a horizontal position also allows removal of the pump from the coating material

container. Ensure that the locking pin locks.

2.0 Operating position I (fig. 9) Swiveling the material feed pump to a vertical position allows the material feed

pump to be immersed in the coating material container.

2.1 Operating position II (fig. 10) Swivel material feed pump to a slanted (45°) postion if using the container suction

system (accessory). In this position, there is open space under the material feed pump.

4.2 Changing the material feed pump position

Danger

Be careful, as the moving parts of the swivel mechanism can crush fingers and feet.

1. Grip handle (fig. 11, item 1) with one hand. 2. Push locking pin (2) with the other hand. 3. Swivel material feed pump

up or down to the desired position, until the locking pin (2) locks into the new position.

4