35

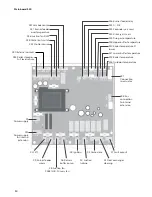

Fuses

Designation

Rating [A]

Description

F1

0.25

Transformer main board

F2

5

Suction fan (X8), burner feeder worm (X9)

F3

10

Ignition (X5)

F4

10

Suction turbine (X4)

F5

10

Heat exchanger cleaning (X2), grate unit (X3)

F6

10

Return pump (X6)

F7

2.5

Lambda sensor heating

F8

2.5

24V power unit

Pin configuration

230 V AC 3-pole

X1, X2, X4, X5, X6, X8, X9, X10

L

N

GND

230 V AC 4-pole

X3 Grate drive

L (Grate close) Wire Nr. 2

L (Grate open) Wire Nr. 3

N Wire Nr. 1

GND

No-voltage 3-pole

X7 Fault output

normally closed

Root

normally open

230VAC 4-pole

X11 Power supply for internal extension modules

L

L switched via STL – not used

N

GND

230 V AC 2-pole

X12 STL

L

L switched

Temperature sensor/analogue input 2-pole

X13 – X18, X23

Input

GND

Lambda sensor 4-pole

X21

Input positive

Input negative

Sensor heating

Sensor heating

Analogue output 3-pole

X26

24 V

Analogue output

Analogue GND

Burner feeder overtemperature/external contact

X27, X30

24 V

Input

Digital input 3-pole

X28, X32, X35, X36

24V brown

Input black

GND blue

CAN Bus 4-pole

X38

24 V

CAN A

CAN B

GND

Summary of Contents for Top Light Zero 18

Page 38: ...38 08 Notes ...

Page 39: ......